SKF Unveils New Brand Identity

- By MT Bureau

- March 06, 2025

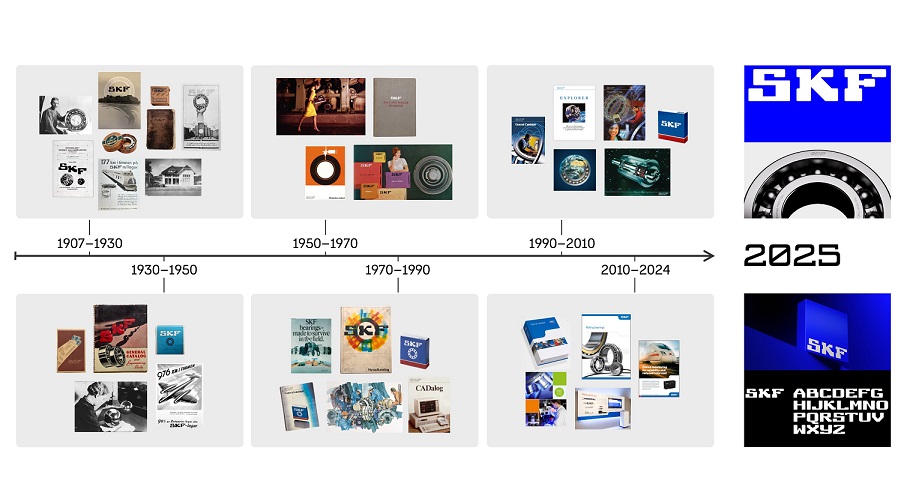

Swedish industrial bearings major SKF is revamping its brand identity, which it said is to help the group to further stand out in the industry, attract new customers and ultimately drive profitability.

The over a century old bearings company is amongst the top players globally when it comes to being a closed partner for industrial and mobility solutions. Rickard Gustafson, President and CEO, SKF, said, “Our brand is the accumulation of everything we do – innovations, values, people, reputation, communication and our desired future state. From a business perspective, we are building favourability among current and potential customers, employees, investors, partners, and beyond. It is a way of earning our place in the world while staying true to our values and purpose.”

Rickard Gustafson, President and CEO, SKF, said, “Our brand is the accumulation of everything we do – innovations, values, people, reputation, communication and our desired future state. From a business perspective, we are building favourability among current and potential customers, employees, investors, partners, and beyond. It is a way of earning our place in the world while staying true to our values and purpose.”

The refresh brand strategy aims to reflect upon SKF’s historical, current and future strengths. The idea is to clearly communicate its impact on the world and public perception towards its innovative and sustainable solutions.

Per Nilsson, Director Communication, SKF, said, "Only a few companies in the world can reduce friction like SKF. Wherever there is rotation, we show up – from bicycles to high-speed trains, from paper mills to washing machines. A fantastic position to have, but also an inspiring story still to be told. We have been fighting friction since 1907 and today it is more relevant than ever before.”

The refreshed brand identity includes a redesigned logo, a fresher blue, a new typeface and more distinctive photography.

Going forward, the company will roll out the brand identity across its marketing communication along with working with its distribution partner.

“Through almost 120 years of innovation, we’ve developed products and solutions that reduce friction. Now we’re stepping that up. Not just reducing friction but actively fighting friction to move the world forward and telling the story about the difference we make,” concluded Gustafson.

Kinetic Communications Adds Automated Controller Manufacturing Line At Pune Facility

- By MT Bureau

- July 01, 2025

Kinetic Communications (KCL), a subsidiary of Kinetic Group, has opened an automated controller manufacturing line at its Pune facility.

The line was inaugurated by Padmashri Dr. Arun Firodia, Chairman, Kinetic Group, Deepak Shikarpur, Director, Kinetic Communication and Ajinkya Firodia, Vice-Chairman, Kinetic Group.

The set-up integrates Surface Mount Technology (SMT) and automated assembly controlled by Human Machine Interface (HMI) and Programmable Logic Controller (PLC) systems.

It will manufacture Motor Controller Units (MCUs), which manage electric vehicle battery and motor functions, including acceleration, braking and energy efficiency. It also produces Power and Driver Board Assemblies and Complete Controller Box Assemblies, capable of placing up to 40,000 components per hour.

The line has a current capacity of 300 units per shift, totaling 180,000 units annually across two shifts.

Ajinkya Firodia, said, "The new fully automated controller line marks a significant stride toward Industry 4.0-driven smart manufacturing. It’s a high-throughput, precision-engineered facility that brings intelligence, speed and scalability to our operations. Every stage is data-driven and benchmarked to global quality standards. This is more than a technological leap – it’s a statement of our commitment to innovation and operational excellence.”

Deepak Shikarpur, Director, Kinetic Communications, added, "This facility is a true reflection of Make in India at its most advanced. With its automation, precision and capability to manufacture smart, feature-rich motor controller units, it positions India on the global map for next-generation EV electronics manufacturing.”

The KCL plant uses 3D Solder Paste Inspection (SPI), Automated Optical Inspection (AOI) and In-Circuit Testing (ICT). Through-hole components are soldered using lead-free dualwave technology. Poka Yoke mechanisms and connected HMI/PLC systems reduce human error and ensure traceability. End-of-Line (EOL) testing and Pre-Dispatch Inspection (PDI) are also conducted.

Incoming Quality Control (IQC) aligns with JESD22 reliability standards, with all components undergoing performance testing and suppliers required to meet RoHS and REACH compliance. KCL aims for Zero PPM defects, increased productivity and enhanced quality.

Garaaz Raises INR 45.5 Million In Seed Round Led By GVFL

- By MT Bureau

- July 01, 2025

Jaipur-based automobile spare parts aggregator start-up Garaaz has raised INR 45.5 million in a seed round led by GVFL.

The start-up aims to deploy the funds to expand its operations in other states, strengthen local distribution, partnerships, on-ground teams, invest in technological innovation (R&D) and hire key talent across technology, sales, marketing and operations.

Incepted in 2019, the startup was founded by Shaleen Agarwal with an aim to bring together multi-brand garages that can seamlessly discover, compare and purchase spare parts from a catalogue of over 8 million units spanning 25 leading car brands. The start-up enables parts discovery, inventory lookup, orders & schemes, account management, orders & CBO, sales & schemes, branch management, workshop management to distributors, OEMs and resellers as well as manufacturers.

Mihir Joshi, Managing Director, GVFL, said, “India has come a long way in terms of online markets. Today, we can buy EV motorcycles on e-commerce platforms. However, the spare parts ecosystem for the auto industry is highly fragmented, with thousands of small distributors, middlemen and local suppliers leading to inefficiencies and a lack of standardisation, making it highly unreliable. Garaaz is addressing the issue by connecting key stakeholders – brands, distributors/retailers, and workshops – while fostering trust and transparency in a traditionally unorganized and complex market.”

Shaleen Agarwal, CEO & Founder, Garaaz, said, “At Garaaz, we’re not just delivering spare parts – we’re powering the heart of India’s workshop economy. Every order, every delivery, every connection is backed by a tech backbone that scales trust, transparency and efficiency across the aftermarket. Our mission is simple: make spare parts accessible, intelligent and instant – with technology so seamless, it feels invisible.”

- ZF Commercial Vehicle Control Systems India

- ZF

- Maruti Suzuki India

- Kalyani Brakes

- Bosch Chassis Systems

- Continental Brakes

- Knorr-Bremse

- Prof. Dr. Peter Laier

- Akash Passey

- P Kaniappan

- Paramjit Singh Chadha

ZF Commercial Vehicle Control Systems India Appoints Paramjit Chadha As New MD

- By MT Bureau

- July 01, 2025

ZF Commercial Vehicle Control Systems India, a leading component supplier in the country, has appointed Paramjit Singh Chadha as its new Managing Director.

A seasoned automotive engineer, Chadha comes with over four decades of extensive experience working across roles and companies. He begun his journey with Maruti Suzuki India and went on to work with brands such as Kalyani Brakes, Bosch Chassis Systems, Continental Brakes and Knorr-Bremse.

In his last role, he led several projects on ESG, manufacturing excellence and digitalisation within the ADM Group as its President and MD. His expertise is particularly strong in safety-critical components, such as brake systems for various vehicle segments.

Prof. Dr. Peter Laier, Member of the Board, Board of Management ZF Group commented, said, “P Kaniappan’s leadership, strategic vision, and commitment have been instrumental in establishing ZF’s strong foundation and continued success in the Indian market. I am delighted to now welcome Paramjit to the ZF Group and I am confident that his rich experience, knowledge and proficiency will prove to be an invaluable asset to the company”.

Akash Passey, President, ZF Group India, noted “We are very happy to welcome Paramjit Chadha as the Managing Director of ZF CVCS India. His experience and expertise in the regional automotive ecosystem will lend positively to the growth of the CV business in the region and will bring in an exciting new chapter for the ZF Group. I also extend my heartfelt appreciation to P Kaniappan, whose remarkable legacy and unwavering dedication have laid a strong foundation for our presence in India. Thank you for your outstanding service."

Remsons Signs Strategic Technology Licensing Deal with Brazil’s AUSUS Automotive to Empower Local OEMs

- By MT Bureau

- June 27, 2025

Mumbai-headquartered automotive engineering and components supplier Remsons Industries has signed a Strategic Technical License Agreement with Brazil-based AUSUS Automotive Systems do Brasil.

As per the understanding, Remsons will collaborate with ASUS Brazil to license proprietary technologies, enabling the development and manufacturing of high-quality products tailored to the local market.

The move aims to introduce advanced technologies for supporting the automotive and electronics industries in Brazil.

Rahul Kejriwal, Executive Director, Remsons, said, "We are excited to partner with ASUS Brazil to bring our technological expertise to the Brazilian market. This collaboration is a significant step towards supporting local OEMs and strengthening the industrial ecosystem in Brazil."

Comments (0)

ADD COMMENT