Witnessing manufacturing modernisation since Maruti Udyog began producing cars in collaboration with Suzuki of Japan at Gurgaon in 1984, the Indian auto industry landscape has drastically changed. Opening up to automation with the installation of some of the best robots available at Kuka, ABB and others, the auto industry has left no stone unturned. Such has been the fervor that Tal, a Tata Motors company, launched a robot called Brabo in 2018 to make manufacturing processes involving the application of sealants, picking and placing of parts, welding and vision inspection reliable and easy to perform. Made with an eye on manufacturing process the world over, the Brabo was tested in over 50 work streams and has so far found use in sectors like lighting, aerospace, software, electronics, plastics, education and logistics sectors apart from the auto industry. Coming from an auto maker that installed 300 Kuka robots to automate the assembly of Sumo and Safari at its Pune plant in 2009, the Brabo has seen many rounds of development and application-preparedness since its launch.

Smart manufacturing trend

Highlighting the smart manufacturing trend, the TAL Brabo robot with payloads of two and 10 kilos has also found favour with companies in Europe and other places. Highlighting the prowess of Artificial Intelligence (AI) and Internet of Things (IoT), the robot is an example of the fast-changing manufacturing canvas. Producing about 1,286 engines per day, the Igatpuri plant of Mahindra & Mahindra became India's first carbon-neutral manufacturing facility by adopting smart manufacturing practices under Industry 4.0 in 2019. It invested in energy efficient technologies among others. It invested in recycling of water and other waste. It invested in solar panels to power some of its processes in the plant. An industry source expressed that the rapidly changing business environment the world over is providing impetus to smart manufacturing. It is driving efficiency enhancements and collaborations, he added. Emphasising on efficiency enhancements and collaborative efforts as key smart manufacturing drivers, an industry expert stated that technologies like AI, Industrial Internet of Things (IIoT), automation, big data and 5G are the biggest triggers. They are touching every aspect of manufacturing, from sourcing of raw materials to final inspection, he quipped.

Industry 4.0

As companies like Lincode (it has collaborated with Switzerland-based Global Automotive Alliance), specialising in AI-powered visual inspection with multiple patent-pending defect detection capabilities, find more and more takers in India, the smart manufacturing shift is continuing to take place despite disruptions. It has, in fact, gained speed in India with the race to successfully accomplish BS VI transition in the last few years. A source in the auto industry mentioned that BS VI transition led to manufacturers upping their global ambitions. Vinay Raghunath, Partner and Leader, Automotive Sector, EY India, averred in a report that automotive shop floors are evolving and adopting digital technologies. This, he added, is happening amid challenges like slowdown in demand, non-availability of labour, concerns on health and safety management on the shop floor. Witnessing disruptions relating to ROI among other factors, as Raghunath has informed, the Indian auto industry has been an early adopter of digital manufacturing techniques.

Working to dial higher efficiency, expertise and superior productivity, the Indian auto industry has been overhauling existing assembly lines, erecting new ones and extensively re-evaluating its manufacturing processes and practices in view of smart manufacturing, especially from an automotive value chain point of view. Taking to Industry 4.0, it is leveraging AI and IoT-based manufacturing technologies to automate further – to engage in machine-to-machine communication (M2M) such that there is self-monitoring as well as self-diagnosing. Taking to Industry 4.0 to tackle unanticipated disruptions like the Covid-19 pandemic, which has put well-oiled supply chains and production lines to the test and made it painfully clear that they in their current form are not as agile or resilient as expected, the auto industry is shifting to smart manufacturing in a big way. It is exploring and experimenting; it is finding new ways. It is doing so as it absorbs a significant change in technologies and products like electrification and EVs.

Operator 4.0 and hyper-intelligence

Investing heavily in data analytics infrastructure and capabilities, the auto industry is leveraging opportunities to digitally transform itself. It is defining the boundaries of physics for data-driven model. It is focusing on digital skills development. It is supporting the rise of Operator 4.0. Taking to collaborative robots that coexist with humans in a workplace, it is transforming its ways of manufacturing significantly. Drawing attention to the semi-conductor shortage and how the auto industry was affected despite using only 10 percent of the production, Vipin Sondhi, Managing Director, Ashok Leyland, explained that the rapidly changing consumer psyche is dictating a move to a completely different technological aspect. Emphasising on material technology, he said smart manufacturing is about digitising and achieving cost competitiveness. It was some two to three years ago that the Chennai-based CV maker began implementing smart manufacturing technologies to mitigate challenges. It took to modernising and digitising existing workplaces to address quality issues that are difficult for human beings to detect and acquire made-to-order or mass customisation capabilities. It took to equipping itself with an ability to expand and contract in tandem with the market conditions even as it took to modularisation of product lines.

Automating its cab panel pressing plant at Hosur in 2019, which increased the output by up to 66 percent, Ashok Leyland has been one of the many automotive OEMs globally that are investing in hyper-intelligent automation. A confluence of AI and Robotic Process Automation (RPA), hyper-intelligent automation is redefining not just Industry 4.0 but also Operator 4.0. It is facing challenges like the high initial acquisition cost in terms of tools, but that isn’t worrying players involved like Tata Consultancy Services, Wipro, Mitsubishi Electric Corporation, Catalytic Inc and Infosys Limited among others. Estimated to grow at a CAGR of 18.9 percent as manufacturers strive to reduce energy consumption, up quality and reliability, and control costs through predictability and data-driven unique insights, hyper-intelligent automation is turning out to be yet another finer aspect of smart manufacturing. It is proving to be a big enabler for automating repetitive tasks – to enhance efficiencies, to take to cloud computing to ensure significantly more flexibility and to achieve scalability and the ability to collaborate and reduce costs.

Increasing visibility, predictability and enhancing control on operations and inventory, hyper-intelligent automation is aiding effective decision-making. Supported by development of new technologies such as 5G, which according to a domain expert, promises the need for speed and flexibility along with the capability to eliminate network instability or downtime, hyper-intelligent automation is helping automotive suppliers like Rane Madras Limited to make efficiency, reliability and cost control gains. In 2018, the company adopted automated solutions of Mistubishi Electric Corporation for its new plant in Gujarat. It led to a significant decrease in energy consumption. Aiding smart manufacturing, technologies like hyper-intelligent automation and 5G are helping the auto industry to achieve resilience and immunity against future uncertainties. They are helping to integrate Information Technology (IT) systems used for data-centric computing with Operational Technology (OT) systems – for data readiness and cyber security, and for the development of digital talent. Technologies like hyper-intelligent automation and 5G are helping to develop cross-functional profiles like engineering-manufacturing, manufacturing-maintenance and safety-security.

Tackling disruptions and smart working environment

Looking at productivity gains, emerging competition and risk aversity in the globalised world as per the EY report, the auto industry is taking to smart manufacturing to achieve significant technology transformations like electromobility as well. Apart from the creation of a smart working environment, it is also looking at the use of new materials, new process guidelines and practices. With health also becoming a disruptive factor in recent times, the auto industry is looking at automation in processes like inbound logistics, production planning, sourcing, press shop, body shop, paint shop, quality control and outbound logistics through data visualisation. With sensors and analytics shaping up, the smart working environment in a factory is coming to include AI-based alerts and fully automated work floors. This is increasingly getting compounded by data collection, historical data and high-quality extensive data mining. Helping to guarantee ROI, smart manufacturing is helping to lower the ‘takt’ time. It is also ironically undermining the involvement of humans on the shop floor.

Reducing the cost of computation, storage and connectivity, smart manufacturing is coming of age with plummeting prices of sensors, 3D printers and robots. Empowering cloud-based manufacturing techniques and a gradual increase in the understanding of emerging technologies, smart manufacturing is providing an advantage in terms of the ability to respond to market changes quickly. Taking to develop a new light-duty truck platform with export ambitions and flexibility in terms of left-hand drive and right-hand drive orientation, VE Commercial Vehicles Ltd took to automating its welding line with robots at its Pithampur plant. It also took to robotising its windshield pasting station among others. Experiencing quality, consistency, efficiency and cost gains, the CV maker is also known to have reduced the takt time and energy consumption. As global ambitions and modularity strike in view of the ability to explore new export markets with a cost competitive BS VI product, the auto industry in India is using embedded sensors, RFID and GPS etc. for smart tracking. It is using smart manufacturing technologies to monitor parameters like temperature, pressure, vibration, machine rpm and flow rate.

Smart flexibility

As part of a shift to smart manufacturing, automakers and suppliers are resorting to flexible manufacturing and AR-based solutions to upskill. They are, in view of the technologies like connected vehicles and EVs, stressing on re-aligning their traditional manufacturing setups with that of the future. Emphasising on quality, resource optimisation, streamlining of business processes and adoption of new emerging technologies, they are closely evaluating the advantages of solutions like digital twins and rapid prototyping using additive manufacturing offer. With ROI on their mind, they are embracing smart manufacturing to move up the value chain.

Mahindra’s 1,000-Acre Nagpur Plant To Anchor SUV, Tractor Expansion

- By Gaurav Nandi

- February 11, 2026

The company is building a 1,000-acre greenfield complex in Nagpur to unlock SUV and tractor capacity as demand across segments begins to outpace supply at its existing plants. The facility will anchor a phased expansion plan even as the company revises tractor growth outlook sharply higher and races to ease production bottlenecks.

Mahindra and Mahindra’s upcoming greenfield complex at Nagpur will be spread across more than 1,000 acres and anchor the automaker’s next phase of capacity expansion with room for 500,000 SUVs and 100,000 tractors annually in a modular, phased build-out starting 2027-28.

The plant, which will also house a dedicated tractor facility within the same campus, is being designed to flex production between new-generation SUVs from Mahindra’s upcoming platforms and rising tractor volumes as the company prepares for sustained demand across segments.

“The Nagpur project gives us the flexibility to scale in a modular way across both SUVs and tractors without overcommitting capacity on day one,” said Chief Executive Officer, Auto and Farm Sector, Rajesh Jejurikar.

The expansion comes amid visible supply constraints at existing facilities in Chakan and Nashik, where strong demand for refreshed models such as the 3XO, Bolero range, Scorpio N and the newly introduced electric SUVs has pushed plants close to their limits.

Mahindra expects de-bottlenecking efforts to unlock an additional 3,000-5,000 units a month in internal combustion models by August-September, alongside 3,000-4,000 units of added EV capacity through the year.

The company said dealer inventory currently stands at 15–20 days, well below its preferred 25–30 day range, reflecting tight supply rather than demand weakness.

Demand momentum has also prompted Mahindra to sharply revise its tractor industry outlook. What was earlier guided as “low double-digit” growth for the year is now expected to land in the 22–24 percent range.

“We had underestimated the strength of the tractor industry. It is likely to be almost twice of what we had originally guided,” Jejurikar said.

On the passenger vehicle side, Mahindra stopped short of offering formal guidance for the next quarter or fiscal year but indicated that industry demand remains robust, with supply rather than orders becoming the limiting factor.

“I think everyone is going to be constrained by capacity because demand right now is stronger than the way supply is able to ramp up,” Jejurikar added.

The automaker is also seeing strong traction for its latest SUV launches. The XUV 7XO is witnessing higher bookings for top-end variants, continuing a trend seen in the XUV700, while the newly introduced electric SUV 9S is drawing customers seeking a more conventional seven-seat SUV format. Diesel continues to account for 70–75 percent of demand for the 7XO.

Jejurikar said there will be no new EV launches in calendar 2026 beyond the already introduced models, with capital expenditure tracking previously announced plans of INR 270 billion over three years, including INR 120 billion earmarked for new electric vehicle platforms.

On the financial side, Mahindra’s standalone results reflected a INR 3.75 billion loss from investments in subsidiaries, associates and joint ventures, up fourfold year-on-year. This was primarily due to impairments in Mahindra’s Japanese arm, which is undergoing restructuring, and Arkun Foundry in Turkey, hit by hyper-inflationary conditions.

“The impairment is largely related to the restructuring of our Japan operations and the impact of hyper-inflation in Turkey on Arkun Foundry,” said Group Chief Financial Officer Amarjyoti Barua.

Jejurikar also pointed to external factors driving cost pressures, particularly rising precious metal prices and currency movements, prompting a 1 percent price increase in the auto portfolio.

“Precious metals and the impact of the dollar are the two key areas where we are seeing tangible increases,” Barua said.

Mahindra’s leadership also sees an opportunity emerging from recent trade agreements. While dismissing concerns that European imports could undercut domestic manufacturing, the company believes the new framework opens a pathway for higher exports of India-made vehicles to Europe at zero duty over time.

“There is an opportunity for us to sell meaningfully more into Europe over time at zero duty, and that is something we will take advantage of,” said Jejurikar.

Group Chief Executive Officer Dr Anish Shah added that broader policy changes, such as GST rate cuts, could have a sustained demand impact beyond immediate price benefits.

“A lower upfront cost for customers will continue to stimulate upgrades and first-time purchases over the longer term,” Dr Shah said.

Indian Auto Retail Starts 2026 With 17.6% Growth

- By MT Bureau

- February 10, 2026

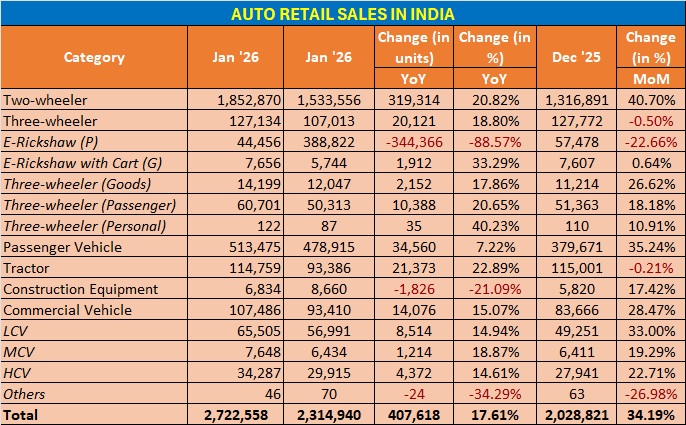

The Federation of Automobile Dealers Associations (FADA) has released the retail sales data for January 2026, which saw the overall industry report a healthy 17.61 percent growth over January 2025.

Last month, a total of 2.72 million vehicles were sold, as compared to 2.31 million vehicles a year ago, and 2.02 million in December 2025. Barring construction equipment (-21.09 percent YoY), all segments posted a healthy growth.

Two-wheeler sales in the country grew by 20.82 percent YoY to 1.85 million units, which saw rural markets contributed 56 percent of this volume, while urban demand grew by 22.19 percent, indicating a recovery beyond festive periods. The passenger vehicle sales at 513,475 units, up 7.22 percent YoY was primarily driven by rural demand at 14.43 percent, as compared to 2.75 percent growth witnessed in the urban segment.

Commercial Vehicles segment grew 15.07 percent to 107,486 units, which saw Light Commercial Vehicles (LCV) grow by 14.94 percent YoY and Heavy Commercial Vehicles (HCV) by 14.61 percent YoY, driven by replacement demand and infrastructure projects.

C S Vigneshwar, President, FADA, said, “January’26 has delivered a strong, broad-based start to the calendar year, with overall vehicle retail at 27,22,558 units, registering 17.61 percent YoY. The growth was powered by continued post-GST momentum, healthy rural cashflows on the back of harvest and weddings and sustained demand visibility across mobility and freight.”

Growth to remain positive

The outlook for February 2026 remains positive, with 72.56 percent of dealers expecting continued growth. Market sentiment is supported by the recent Budget’s focus on infrastructure and agriculture, alongside stable interest rates.

For the February-April period, 79.70 percent of dealers anticipate growth. Two-wheeler demand is expected to be sustained by wedding season purchases and EV adoption, while commercial vehicle sales are predicted to benefit from financial year-end buying and infrastructure activity. Potential constraints include model-specific supply shortages and possible disruptions related to upcoming elections in select states.

- Society of Indian Automobile Manufacturers

- SIAM

- Automotive Design Challenge

- Prashant K Banerjee

- G Sathiysaeelan

- Ashok Leyland

- Andreas Kurbos

- StudioKurbos

- Saurab Singh

- Maruti Suzuki India

- Tata Motors

- Stellantis

- Royal Enfield

- Greaves Electric Mobility

- Kiska

SIAM Hosts 20th Styling & Design Conclave in Goa

- By MT Bureau

- February 09, 2026

The Society of Indian Automobile Manufacturers (SIAM) held the 20th Styling & Design Conclave and the 18th Automotive Design Challenge (ADC) in Goa on the theme of ‘Collaborative Creativity: Building India’s Mobility Design Ecosystem’.

The event gathered designers, industry experts and academics to discuss vehicle aesthetics, form and consumer expectations. During the event, SIAM launched a white paper titled ‘Evolution of Automotive Design in India.’

The conclave focused on the necessity of building design capabilities through partnerships between the automotive industry and academic institutions.

The 18th edition of the ADC featured 53 students from various design colleges. Participants presented concepts focused on future mobility needs, providing a platform for entry-level designers to showcase innovation in vehicle styling.

Speakers across two sessions addressed the integration of aesthetics with functionality, material innovation and sustainability. Discussions highlighted the shift toward design-led differentiation in the Indian market.

Prashant K Banerjee, Executive Director, SIAM, said, “Meaningful mobility solutions emerge from the confluence of sustainability, desirability, and affordability. These three essential pillars that must work together to address local needs while aligning with evolving environmental priorities.”

G Sathiyaseelan, Chairman, SIAM Styling & Design Group and Design Director, Ashok Leyland, said, “Understanding user experience must go beyond acknowledging problem areas and be rooted in empathy and a solution-driven mindset, with a clear focus on enabling gender-sensitive transportation and strengthening last-mile connectivity to create truly inclusive mobility solutions.”

Andreas Kurbos, Founder & CEO, StudioKurbos, added, “As design continues to evolve globally, India’s story can achieve stronger resonance by drawing from its rich culture and legacy. With design tools becoming increasingly democratised, identity becomes a powerful differentiator, making it essential to deeply understand audiences and co-create distinctive user experiences, while strengthening design education to shape the future of design.”

Saurabh Singh, Co-Chairman, SIAM Styling & Design Group and Senior VP, Maruti Suzuki India, added, “Shaping India through thought-provoking and emotionally engaging dialogue is essential to spark deeper conversations and meaningful action, and the country must set its sights on a bolder, more ambitious vision for its automotive future.”

The sessions included contributions from design leads at Maruti Suzuki, Tata Motors, Stellantis, Royal Enfield, Greaves Electric Mobility and Kiska. Topics included the use of bio-sourced polymers, digital modelling and the development of next-generation styling for electric vehicles.

Kia Connect Appoints Olivier Pascal As President And CEO

- By MT Bureau

- February 06, 2026

Kia Connect has named Olivier Pascal as President and Chief Executive Officer with effect from 1 January 2026. He brings over 15 years of automotive industry expertise to the position, having most recently acted as General Manager of Connected Cars, where he led European initiatives for connected vehicle experiences and data development. His career includes leadership across engineering, sales, marketing and technology functions at various dealership, regional and global levels. In his new capacity, Pascal will oversee the company’s connectivity, digital, data and charging strategies, emphasising customer experience, innovation and sustainable growth throughout Europe.

This leadership transition sees Marc Hedrich and Pablo Martínez Masip departing from their positions as President & CEO and COO, respectively. During their tenure, they were instrumental in driving strategic and operational performance across European markets. Hedrich moves to the role of President for Kia France, while Martínez Masip continues as Vice President of Product and Marketing at Kia Europe.

Kia Connect is dedicated to enhancing the customer journey through a fully integrated digital ecosystem, which now supports nearly two million users. The platform combines connected car services, digital mobility solutions and charging infrastructure, aligning with Kia’s broader shift towards software-defined and electrified mobility. Central to this ecosystem is the Kia App, launched last May, which consolidates connectivity, charging and ownership services into one interface. The app provides features such as remote status checks, vehicle diagnostics and charging control, with regular over-the-air updates introducing continual improvements informed by user feedback.

A recent December update introduced a 3D visualisation feature for the EV9 model, allowing drivers to view an accurate digital representation of their own vehicle’s configuration, including exterior colour and wheel design. This addition aims to create a more intuitive and tangible connection between the driver and their car through the app. Following an evaluation period, Kia intends to extend this 3D visualisation to other electric vehicle models in 2026.

Pascal said, “Kia Connect’s mission is to make every driving and charging journey smarter, safer, more convenient and more personal. In 2026, we will deliver tangible value for our B2C and B2B customers and partners, higher-quality features, a truly personalised digital experience, scalable B2B services and a robust charging solution. By combining innovation, unique customer experiences, responsible data use and operational rigour, we will build sustainable growth and a platform that supports Kia brand differentiation and business success in Europe.”

Comments (0)

ADD COMMENT