Henkel Adhesives Plant In India To Serve Emerging Markets

- By 0

- April 05, 2020

The phase I and II of the plant, set up investing INR 400 crore, will boost its capabilities to serve customers across sectors including flexible packaging, automotive, agriculture and construction equipment, general industry and metals. The plant which will cater to the local and export markets employs 300 people. The phase III and IV will be launched later at an estimated cost of INR 400 crore.

“India is one of the most important emerging markets with tremendous growth opportunities for our adhesives business,” Jan-Dirk Auris, Member of the Management Board and Executive Vice President, Adhesive Technologies business unit, Henkel AG & Co. KGaA, said. “We have application experts across manufacturing industries worldwide and work closely with our customers and partners. Our trusted brands and leading solutions based on our unmatched portfolio of 40 technologies create sustainable value for our customers. With the launch of this state-of-the-art, multi-technology manufacturing facility, we have created capacities to meet the demand for our high impact solutions in this dynamic market. This investment will enable us to further drive profitable growth,” he added.

Momentum in megatrends in the automotive sector will fuel demand for the company’s adhesive products, which help reduce vehicle’s weight. “Electric and connected vehicles need more adhesives than IC engine vehicles. We will continue to bring out products and solutions based on consumer demand and suitable for the new mobility, connectivity and sustainability,” Auris said.

The new plant is part of Henkel’s big bet on the emerging markets. Half of its total sales of USD 20 billion is from them. “India is the largest among the top 3 emerging markets. We believe tremendous demand will come from India for adhesives in the next decade. Henkel’s products are ‘invisible but essential’ and work as enablers for its consumers to improve efficiency and quality. Being a highly impactful solutions supplier, we also need to manage the risks,” he said.

Smart Factory

The Kurkumbh site is equipped with technologies to ensure traceability and transparency by ensuring built-in quality. End-to-end digitalisation of the plant operations has enabled digitised workflows; thus, making manufacturing more efficient. It deploys closed material handling systems and high level of process automation. For the first time, as a global pilot in Henkel, the site has implemented deep integration of process automation with Smart Factory (Industry 4.0).

The site meets the highest standards of sustainability. It is among the very few chemical manufacturing sites to be awarded the LEED Gold Certificate by the US Green Building Council based on a holistic energy efficiency concept. About 10 percent of its power consumption comes from captive solar energy and 16 percent of the annual water requirement is met by rainwater harvesting. Air and waste water discharges are monitored online.

Shilip Kumar, President, Henkel India, said, “We will continue to invest in local manufacturing as it gives our Adhesive Technologies business in India a strategic advantage. The Kurkumbh manufacturing site is a very important milestone of Henkel’s journey in India. This site will not only cater to the Indian market but also markets in the Middle East, Africa and South Asia. As market leaders in this industry, our focus is to offer high impact solutions to our customers and convert latent market potential into profitable growth.”

Henkel Adhesive Technologies is a global leader in adhesives, sealants and functional coatings. The business unit serves around 130,000 customers in over 800 industrial areas with tailor-made products and technologies used in a wide array of consumer goods and industrial products. (MT)

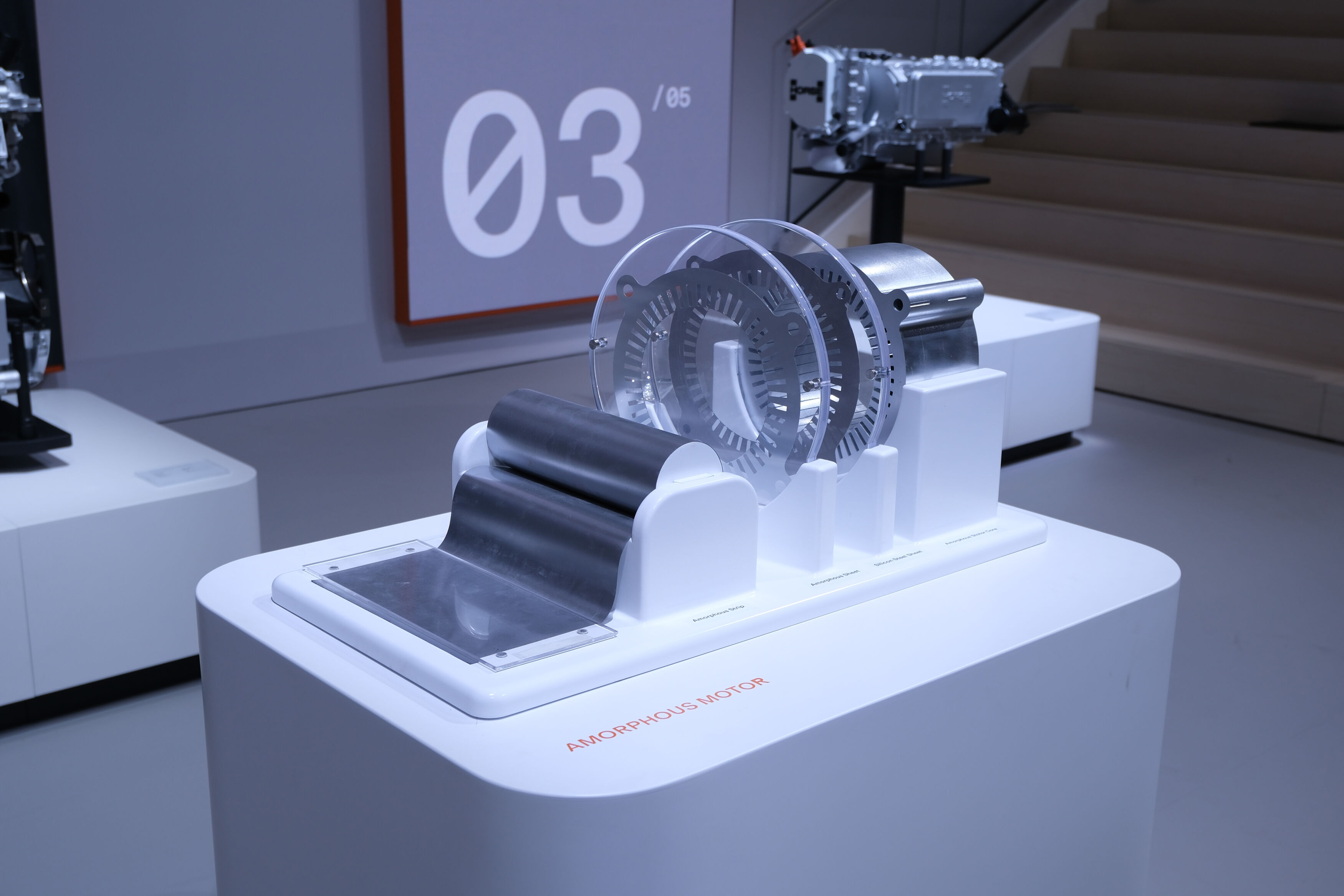

Horse Powertrain Debuts Groundbreaking ‘Amorphous Motor’ Technology

- By MT Bureau

- March 05, 2026

Horse Powertrain, a global leader in advanced and low-emission powertrain solutions, has unveiled its new Amorphous Motor technology, marking a significant step forward in hybrid transmission systems. The innovation was introduced to the public for the first time at the IAA Summit 2025.

Central to the motor’s design is the use of amorphous steel, a material known for its exceptional strength, durability and magnetic properties. This material allows the company to significantly reduce the thickness of the steel laminations used in the motor’s stator. While traditional motors use steel sheets of a standard thickness, the layers in the Amorphous Motor are only 0.025 mm thick, roughly one-tenth of the conventional standard.

This ultra-thin construction, combined with the material’s high conductivity, leads to a 50 percent reduction in stator iron losses compared to similar designs. Consequently, the motor achieves a record-setting efficiency of 98.2 percent, all while delivering a maximum output of 140 kW and 360 Nm of torque.

The practical impact for hybrid vehicles is a one percent improvement in overall fuel and energy efficiency. This reduction in consumption supports automotive manufacturers in their efforts to develop a new wave of lower-emission models. This breakthrough is part of a broader strategy by Horse Powertrain to advance hybrid and combustion technologies through a technologically neutral approach to decarbonisation. The company’s global capabilities, which include 17 manufacturing sites, five research and development centres and a workforce of 19,000, continue to drive this series of high-efficiency innovations.

Ingo Scholten, Deputy Chief Technology Officer, Horse Powertrain, said, “This latest innovation demonstrates Horse Powertrain’s continued commitment to research and development, providing suppliers and OEMs with the tools to raise the bar on when it comes to fuel economy and emissions performance. The Amorphous Motor is an ideal tool to power a new generation of high-efficiency range extended EVs, hybrids and plug-in hybrids, ensuring these technologies continue to play a substantial role in automotive’s decarbonisation journey.”

Tata Elxsi Launches DevStudio.ai To Automate Automotive Software Engineering

- By MT Bureau

- March 05, 2026

Tata Elxsi has launched DevStudio.ai, a multi-agent generative AI (GenAI) platform designed to accelerate the automotive software development lifecycle (SDLC). The solution is purpose-built for OEMs, system suppliers and semiconductor companies to address the engineering requirements of software-defined vehicles (SDVs).

DevStudio.ai is aligned with ASPICE (Automotive Software Process Improvement and Capability dEtermination) standards. It utilises a multi-agentic architecture that allow AI co-engineers to collaborate with human teams across engineering workflows. The platform is compatible with cloud-based infrastructure and air-gapped on-premise environments to comply with enterprise AI policies.

Unlike general-purpose AI tools, DevStudio.ai focuses on the complexity and safety requirements of the automotive sector. It supports the ASPICE V-cycle stages, including requirements engineering, architecture, implementation, and qualification testing.

The platform provides several capabilities:

- Traceability: Maintains end-to-end links across the engineering lifecycle.

- Toolchain Integration: Connects with existing OEM and Tier-1 engineering software environments.

- LLM Support: Operates with multiple Large Language Models (LLMs).

- Domain Coverage: Supports software development for body, chassis, infotainment, and SDV architectures.

The platform has been deployed in select programmes by global OEMs and suppliers in North America, Japan and India. Early use cases have reported productivity gains and reduced time-to-market for safety-critical systems.

Sundar Ganapathi, Chief Technology Officer – Automotive, Tata Elxsi, said, “The automotive industry is at an inflection point. Competitive pressures now demand software development at China speed. At the same time, companies must maintain automotive-grade quality and meet global industry standards. DevStudio.ai helps address this challenge. It brings the power of generative AI into the automotive software development lifecycle. This enables OEMs and suppliers accelerate development, while maintaining the rigor required for safety-critical automotive systems.”

Pallavi Dalal, Head – Automotive GenAI and AI Practice, Tata Elxsi, added, “DevStudio.ai represents the culmination of intensive research and development between our automotive domain and GenAI specialist teams. We see the future of automotive software development where an AI co-engineer works alongside every engineer. To realise this vision, we are partnering with the entire innovation ecosystem, from leading GenAI companies to hyperscalers, to build and scale DevStudio.ai. This is Future forward for automotive engineering.”

- Mercedes-Benz Research and Development India

- MBRDI

- Indian Institute of Technology Delhi

- IIT Delhi

- Nirat Ray

- Saurabh Saxena

- Manu Saale

- Preeti Ranjan Panda

MBRDI And IIT Delhi Sign 5-Year Agreement For Advancing Industry-Academia Research

- By MT Bureau

- March 05, 2026

Mercedes-Benz Research and Development India (MBRDI) and the Indian Institute of Technology Delhi (IIT Delhi) have announced a five-year Master Research Agreement (MRA) to facilitate joint research programmes and knowledge development between industry and academia.

The collaboration focuses on technologies including quantum systems, materials, neuromorphic engineering and electric mobility. The initiative seeks to combine academic research with engineering requirements to develop intellectual property and technology solutions.

The first phase of the agreement involves a project centred on quantum sensors and battery systems. This research is led by Prof. Nirat Ray from the Department of Materials Science and Engineering and Prof. Saurabh Saxena from the Centre for Automotive Research and Tribology.

The partnership will concentrate on:

- Quantum Technologies: Development of sensors for vehicle systems.

- Future Materials: Research into substances for automotive engineering.

- Neuromorphic Engineering: Mimicking biological neural structures for computing.

- Electric Mobility: Advancing battery systems and power electronics.

The teams will work on interdisciplinary research, prototype development, and validation of technologies intended for the mobility sector.

Manu Saale, Managing Director and CEO, Mercedes-Benz Research and Development India, said, “This year marks 140 years since the invention of the automobile, a chapter that reflects the beginning of Mercedes‑Benz’s journey in shaping mobility. MBRDI is also celebrating a milestone as we mark 30 years of engineering excellence in India. We envision a future where academia and industry are systemically partnering to realise real-world challenges and provide meaningful breakthroughs. In that context, our collaboration with IIT Delhi is a significant leap for our legacy of innovation, helping us redefine mobility faster and better. Together, we aim to shape solutions that make a difference today and in the years ahead.”

Prof. Preeti Ranjan Panda, Dean of Corporate Relations at IIT Delhi, stated, “We are pleased to partner with MBRDI in this collaboration, which builds upon IIT Delhi's commitment to enable knowledge exchange and co-creation with industry partners. Through this initiative, the Institute seeks to advance high-quality research and generate impactful innovations that enable sustainable, affordable, and future-ready mobility. Our objective is to develop solutions that address India’s mobility challenges while establishing new benchmarks for global impact.”

3ev Industries And 3eco Systems Partner With Cautio To Deploy AI Dash Cameras Across 10,000 E3Ws

- By MT Bureau

- March 05, 2026

3ev Industries, a Bengaluru-based three-wheeler electric vehicle (EV) OEM manufacturer, and 3eco Systems, a full-stack EV logistics platform, have entered into a strategic partnership with Cautio, one of India’s leading video telematics companies, to install the latter's AI-powered dash camera systems across their electric three-wheeler fleet. The collaboration involves installing systems from Cautio into 10,000 electric three-wheelers. This initiative is designed to enhance protection for drivers, passengers and the wider community, with over 1,200 vehicles already operational in Bengaluru and Chennai. Crucially, Cautio’s dashcams will become a standard factory-installed feature on all new vehicles produced by 3ev.

This move represents a significant shift in India's electric mobility landscape by establishing safety as a fundamental, built-in component from the manufacturing stage. The partnership aims to create a comprehensive data network that links the original equipment manufacturer with the fleet operator while prioritising driver welfare and using data-driven accountability as a key market advantage. As electric fleets expand, the focus is expected to move beyond simply electrifying vehicles to incorporating intelligent systems that ensure safety and operational efficiency.

The decision to collaborate with Cautio followed a rigorous assessment of various global and domestic telematics platforms. Key evaluation criteria included performance in edge computing, the precision of real-time alerts and device durability in challenging environments characterised by high temperatures and dust. A pivotal factor was Cautio’s India-centric design philosophy. Unlike systems developed for highway driving in mature markets, Cautio’s technology is specifically tailored for the complexities of Indian urban conditions, such as congested traffic, unreliable 4G connectivity and extreme weather. Its architecture processes data directly on the device, ensuring core safety functions remain operational even without a stable cloud connection, thereby minimising latency and blind spots.

The AI-driven system employs computer vision to continuously monitor driver behaviour, issuing instant alerts upon detecting signs of fatigue, distraction or mobile phone usage. Concurrently, Advanced Driver Assistance Systems (ADAS) analyse the road environment to warn of potential collisions and lane deviations, a critical function in India’s mixed-traffic scenarios. All trip data is consolidated into a centralised dashboard, offering fleet managers real-time, comprehensive oversight of their operations.

Beyond the hardware installation, the multi-year agreement includes a joint commitment to research and development, driver training and community road safety initiatives. The collective goal is to develop a scalable and structured approach to safety within the electric three-wheeler sector. As citywide fleet electrification progresses and safety regulations evolve, the integration of such embedded AI systems is anticipated to become increasingly vital to operational protocols and risk mitigation strategies.

Suman Mishra, Director, 3eco Systems, said, “Our objective was not just to add monitoring hardware but to deploy technology that meaningfully supports drivers on the road.”

Karan Kadaba, Director, 3ev Industries, said, “Following a detailed evaluation across global and domestic platforms, Cautio emerged as the right partner, combining technical capability with a deep understanding of Indian operating conditions. Other platforms required reliable 4G connectivity that simply does not exist across all our routes. This collaboration reflects our continued focus on building a safety-first operating framework for drivers, fleet partners and passengers.”

Ankit Acharya, Co-Founder & CEO, Cautio, said, “What we are building with 3ev Industries and 3eco Systems is not a vendor-client relationship. It is a shared mission. The electric three-wheeler driver is the new face of India’s urban mobility workforce. These are young people building livelihoods, serving communities, connecting cities. They deserve the same level of safety that protects drivers in premium fleets. But safety cannot stop at a device – it must extend to how we train drivers, how we develop technology and how we hold ourselves accountable to the communities we serve. India is asking for safer roads. With 3ev and 3eco, we are answering. This is more than a deployment. This is the start of building a safer country.”

Comments (0)

ADD COMMENT