Toyota has accelerated its ‘Green Wave Project’ commemorating this year’s environment month. It is aimed at enhancing its nature conservation activity in the community with the company distributing saplings to its employees, under its sixth challenge that is termed as ‘Establishing a Future Society in Harmony with Nature’ and looks to contribute to the Toyota Environmental Challenge 2050.

While the eco campaign continues to drive active community involvement to promote greenery, through employee engagement, Toyota Kirloskar Motor (TKM) has successfully distributed over 7000 saplings to its employees, marking significant progress towards its 8,000-sapling target set under its plantation activity.

With TKM employees encouraged to plant and nurture the distributed saplings within their neighbourhoods and submit periodic reports on plant growth, the it is noteworthy to mention about Toyota’s tree plantation activities that are strongly driven by adopting a unique concept namely the ‘Miyawaki Method of Afforestation’ since 2009, and TKM was the first corporate in India to implement such plantation methodology. TKM’s steadfast commitment to sustainability and ecological restoration is yielding remarkable results, as evidenced by the numerous advantages of the Miyawaki approach. A comprehensive study conducted in collaboration with experts from Bangalore University revealed that the Miyawaki method excels in carbon sequestration, capturing an impressive 30.86 tonnes of carbon per acre.

By doing so, TKM not only restored native habitats but also created self-sustaining ecosystem that contribute to a healthier planet. Under the guidance of Late Dr Akira Miyawaki himself, TKM initiated its maiden Miyawaki plantation drive, way back in 2009, marking a significant milestone in its journey towards conservation of greenery and eco-consciousness. Since that momentous day, TKM's plantation drives have continued to evolve and expanded to 112 acres of green cover within the factory premises, out of which 32 acres of afforestation has been developed using Miyawaki method. Today, Toyota’s manufacturing facility, located in Bidadi (on the outskirts of Bengaluru) proudly boasts more than 328,000 trees of over 790 native species planted within its premises. The results have been truly awe-inspiring with a remarkable increase in biodiversity observed over the years.

From a mere 181 plant species, the count has surged to an impressive 790, while the number of faunal species has risen from 76 to 284. The vibrant ecosystem now encompasses 88 bird varieties, 38 butterfly species, 107 insects, 17 reptiles, 8 mammals, and 6 amphibians, reflecting the successful development of a thriving native forest ecosystem.

In addition, TKM has created an experiential environmental learning centre ‘Ecozone’ (spread across 25 acres with 17 theme parks and home to 65,000 trees with 650 native species) for children, teachers, community members and other stakeholders, within its manufacturing facility aimed at creating the environment leaders and change champions for the future, to usher in desired behavioural change in the communities. This green zone depicts the creation of dense forest within the plant facility using the ‘Miyawaki Concept’ of plantation. The forests are dominantly planted with species of 4 major forest types such as Dry Deciduous, Moist Deciduous, Semi-evergreen and Evergreen Forest, covering 21 different sub-concepts such as Pollination meadows, herbal garden, plants for spices etc. So far, more than 42,000+ students & other stakeholders have been covered through ecozone initiative.

B Padmanabha, Executive Vice President and Director of Manufacturing - Toyota Kirloskar Motor, averred, “At Toyota Kirloskar Motor, we recognise that environmental and social sustainability are just as crucial as economic progression. Guided by Toyota’s Global Environmental Challenge 2050 (six challenges announced in 2015), our sustainability efforts are far reaching that go beyond product zero emissions. While the first three challenges seek to achieve zero carbon emissions covering the entire life cycle of our products, across manufacturing operations as well as our value chain, the last three challenges focus to achieve water conservation, establishing recycled based society and living in harmony with nature.”

“We believe that a sustainable future is built through collective action and community involvement, as exemplified by one of our eco initiatives - Green Wave Program that covers afforestation (plantation drives, distribution of saplings), sharing best practices (e.g. Miyawaki plantation methodology), creating awareness on nature conservation and imbibing good eco behaviour (Toyota Ecozone – Experiential Eco Learning). Together with our employees and other stakeholders, we aim to catalyse positive change in the community to safeguard the environment to the future,” he added.

BYD Unveils Second-Generation Blade Battery With Flash Charging Tech

- By MT Bureau

- March 06, 2026

Chinese automotive major BYD has revealed its second-generation Blade Battery alongside FLASH Charging technology, aimed at improving charging speeds and battery performance in low temperatures.

The system achieves a claimed charge from 10 percent to 70 percent state of charge (SOC) in five minutes, and reaches 97 percent in nine minutes. In temperatures of -30deg C, the charging time from 20 percent to 97 perrcent increases by three minutes compared to performance at room temperature.

The second-generation Blade Battery increases energy density by 5 percent over the previous version. To manage thermal loads during rapid charging, BYD integrated a ‘Lithium-Ion High-Speed Channel’ and a thermal management system.

Key technical specifications include:

- Range: The Denza Z9GT, equipped with this battery, achieves a range of 1,036 km.

- Thermal Management: Full-spectrum systems to regulate heat dissipation.

- Safety Standards: The battery has passed national safety tests regarding puncture and thermal runaway.

- Infrastructure: A world-leading single-connector output of 1500 kW.

BYD plans to build 20,000 FLASH Charging Stations in China by end-2026, with a global rollout scheduled to follow. These stations will feature a pulley-based charger design to improve user ergonomics and keep cables off the ground.

To manage the high-power requirements of 1500 kW charging, the stations use energy storage systems to buffer the demand, reducing the load on the local power grid.

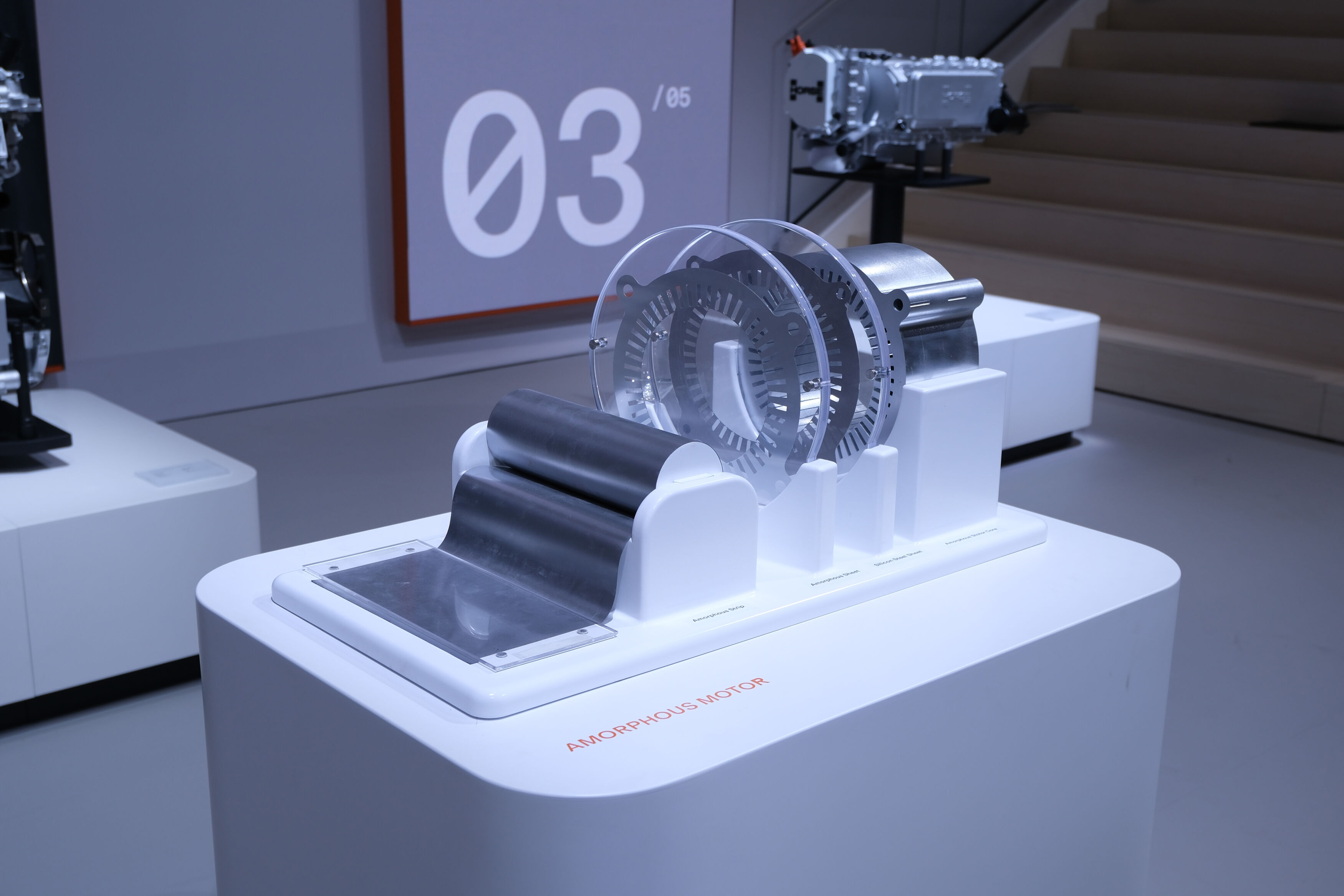

Horse Powertrain Debuts Groundbreaking ‘Amorphous Motor’ Technology

- By MT Bureau

- March 05, 2026

Horse Powertrain, a global leader in advanced and low-emission powertrain solutions, has unveiled its new Amorphous Motor technology, marking a significant step forward in hybrid transmission systems. The innovation was introduced to the public for the first time at the IAA Summit 2025.

Central to the motor’s design is the use of amorphous steel, a material known for its exceptional strength, durability and magnetic properties. This material allows the company to significantly reduce the thickness of the steel laminations used in the motor’s stator. While traditional motors use steel sheets of a standard thickness, the layers in the Amorphous Motor are only 0.025 mm thick, roughly one-tenth of the conventional standard.

This ultra-thin construction, combined with the material’s high conductivity, leads to a 50 percent reduction in stator iron losses compared to similar designs. Consequently, the motor achieves a record-setting efficiency of 98.2 percent, all while delivering a maximum output of 140 kW and 360 Nm of torque.

The practical impact for hybrid vehicles is a one percent improvement in overall fuel and energy efficiency. This reduction in consumption supports automotive manufacturers in their efforts to develop a new wave of lower-emission models. This breakthrough is part of a broader strategy by Horse Powertrain to advance hybrid and combustion technologies through a technologically neutral approach to decarbonisation. The company’s global capabilities, which include 17 manufacturing sites, five research and development centres and a workforce of 19,000, continue to drive this series of high-efficiency innovations.

Ingo Scholten, Deputy Chief Technology Officer, Horse Powertrain, said, “This latest innovation demonstrates Horse Powertrain’s continued commitment to research and development, providing suppliers and OEMs with the tools to raise the bar on when it comes to fuel economy and emissions performance. The Amorphous Motor is an ideal tool to power a new generation of high-efficiency range extended EVs, hybrids and plug-in hybrids, ensuring these technologies continue to play a substantial role in automotive’s decarbonisation journey.”

Tata Elxsi Launches DevStudio.ai To Automate Automotive Software Engineering

- By MT Bureau

- March 05, 2026

Tata Elxsi has launched DevStudio.ai, a multi-agent generative AI (GenAI) platform designed to accelerate the automotive software development lifecycle (SDLC). The solution is purpose-built for OEMs, system suppliers and semiconductor companies to address the engineering requirements of software-defined vehicles (SDVs).

DevStudio.ai is aligned with ASPICE (Automotive Software Process Improvement and Capability dEtermination) standards. It utilises a multi-agentic architecture that allow AI co-engineers to collaborate with human teams across engineering workflows. The platform is compatible with cloud-based infrastructure and air-gapped on-premise environments to comply with enterprise AI policies.

Unlike general-purpose AI tools, DevStudio.ai focuses on the complexity and safety requirements of the automotive sector. It supports the ASPICE V-cycle stages, including requirements engineering, architecture, implementation, and qualification testing.

The platform provides several capabilities:

- Traceability: Maintains end-to-end links across the engineering lifecycle.

- Toolchain Integration: Connects with existing OEM and Tier-1 engineering software environments.

- LLM Support: Operates with multiple Large Language Models (LLMs).

- Domain Coverage: Supports software development for body, chassis, infotainment, and SDV architectures.

The platform has been deployed in select programmes by global OEMs and suppliers in North America, Japan and India. Early use cases have reported productivity gains and reduced time-to-market for safety-critical systems.

Sundar Ganapathi, Chief Technology Officer – Automotive, Tata Elxsi, said, “The automotive industry is at an inflection point. Competitive pressures now demand software development at China speed. At the same time, companies must maintain automotive-grade quality and meet global industry standards. DevStudio.ai helps address this challenge. It brings the power of generative AI into the automotive software development lifecycle. This enables OEMs and suppliers accelerate development, while maintaining the rigor required for safety-critical automotive systems.”

Pallavi Dalal, Head – Automotive GenAI and AI Practice, Tata Elxsi, added, “DevStudio.ai represents the culmination of intensive research and development between our automotive domain and GenAI specialist teams. We see the future of automotive software development where an AI co-engineer works alongside every engineer. To realise this vision, we are partnering with the entire innovation ecosystem, from leading GenAI companies to hyperscalers, to build and scale DevStudio.ai. This is Future forward for automotive engineering.”

- Mercedes-Benz Research and Development India

- MBRDI

- Indian Institute of Technology Delhi

- IIT Delhi

- Nirat Ray

- Saurabh Saxena

- Manu Saale

- Preeti Ranjan Panda

MBRDI And IIT Delhi Sign 5-Year Agreement For Advancing Industry-Academia Research

- By MT Bureau

- March 05, 2026

Mercedes-Benz Research and Development India (MBRDI) and the Indian Institute of Technology Delhi (IIT Delhi) have announced a five-year Master Research Agreement (MRA) to facilitate joint research programmes and knowledge development between industry and academia.

The collaboration focuses on technologies including quantum systems, materials, neuromorphic engineering and electric mobility. The initiative seeks to combine academic research with engineering requirements to develop intellectual property and technology solutions.

The first phase of the agreement involves a project centred on quantum sensors and battery systems. This research is led by Prof. Nirat Ray from the Department of Materials Science and Engineering and Prof. Saurabh Saxena from the Centre for Automotive Research and Tribology.

The partnership will concentrate on:

- Quantum Technologies: Development of sensors for vehicle systems.

- Future Materials: Research into substances for automotive engineering.

- Neuromorphic Engineering: Mimicking biological neural structures for computing.

- Electric Mobility: Advancing battery systems and power electronics.

The teams will work on interdisciplinary research, prototype development, and validation of technologies intended for the mobility sector.

Manu Saale, Managing Director and CEO, Mercedes-Benz Research and Development India, said, “This year marks 140 years since the invention of the automobile, a chapter that reflects the beginning of Mercedes‑Benz’s journey in shaping mobility. MBRDI is also celebrating a milestone as we mark 30 years of engineering excellence in India. We envision a future where academia and industry are systemically partnering to realise real-world challenges and provide meaningful breakthroughs. In that context, our collaboration with IIT Delhi is a significant leap for our legacy of innovation, helping us redefine mobility faster and better. Together, we aim to shape solutions that make a difference today and in the years ahead.”

Prof. Preeti Ranjan Panda, Dean of Corporate Relations at IIT Delhi, stated, “We are pleased to partner with MBRDI in this collaboration, which builds upon IIT Delhi's commitment to enable knowledge exchange and co-creation with industry partners. Through this initiative, the Institute seeks to advance high-quality research and generate impactful innovations that enable sustainable, affordable, and future-ready mobility. Our objective is to develop solutions that address India’s mobility challenges while establishing new benchmarks for global impact.”

Comments (0)

ADD COMMENT