Kuka bets on flexible production and logistics solutions

- By Bhushan Mhapralkar

- August 12, 2021

Supporting a smart manufacturing shift across industry sectors by offering robot systems, Automated Guided Vehicles (AGVs), mobility solutions (mobile platforms, mobile robots etc.) and technologies (arc welding, assembly, bonding and sealing, die casting, extrusion etc.), Kuka is confident of its new operating ecosystem iiQKA significantly simplifying robot use. Forming the base of an entire ecosystem that provides access to a powerful selection of components, programmes, apps, services and equipment that are easy to install, operate and use, iiQKA is designed and developed to facilitate newcomers to implement automation without specialised training. Also announcing the upgradation of its simulation software Kuka.Sim.4.0, Kuka is confident of automation benefitting in the medium-term against Covid-19 disruption. As per Peter Mohnen, CEO, Kuka AG, automation can be beneficial in the medium-term against the Covid-19 disruption for manufacturers rethinking their vulnerable, globally networked production and supply chains.

Big shift to flexible automation systems

Stating in his address to the shareholders in the 2020 annual report that the company implemented a cost-cutting drive and focused on a stable financial position, Mohnen averred that Kuka was one of the very few ‘full-range’ suppliers. Keeping a close eye on the developments taking place across the world markets that it is presently in, the company – with sales revenues of EUR 2.6 billion and an employee strength of 14,000 – is confident of its Kuka.Sim.4.0 software to help reach a new level of planning reliability, simplicity and cost efficiency. Stressing on the upgraded software facilitating easy offline programming of the robot and fast cycle time analysis, Kuka is anticipating a big shift to flexible automation solutions with quickly adaptable production cells instead of rigid systems. It is highlighting the prowess of Kuka.Sim.4.0 software in its ability to support the import of CAD data that aids configuration of safety spaces graphically in 3D and to simulate the stopping behaviour of robots.

Affected in 2020 as projects were postponed or abandoned completely, Kuka is of the view that the auto industry is facing a fundamental structural transformation that offers opportunities but poses enormous challenges at the same time. Confident that the Kuka.Sim.4.0 software will particularly aid components suppliers with its ability to facilitate the planning of robot applications across industry sectors, including auto, the company is looking at a growing use of new technologies such as AGVs and AI-based software solutions. Helped by China’s auto industry’s tremendous thrust on robot installation since 2016 in terms of growth, Kuka is banking on the upgraded software’s capability in significantly reducing the area required by a cell. Roland Ritter, Portfolio Manager, Kuka AG, mentioned that it also contains a new robot language called the ‘Kuka Robot Language’ (KRL), which provides two user views for programming the robot. One view is for the experts and the other is for beginners. Ensuring same data is being worked upon by the virtual controller and the real controller, the Kuka.Sim.4.0 supports the new KR Scara and KR Delta robots from its manufacturer. It also assures 100 percent data consistency.

Features, and more features

Aiding the creation of a customised component library using own CAD data along with Kuka.Sim.Modeling add-on, the Kuka.Sim.4.0 software is also supported by a new ‘Connectivity’ add-on that allows users to commission the cell virtually and create a digital twin for greater planning reliability and the best possible implementation. Interestingly, the customised component library could be as kinematic systems, sensors, material flow or physical behaviour. Using behavioural emulators such as WinMOD and SIMIT, the software, with the Arc Welding add-on, aids users to speed up their offline programming for welding applications. The approach positions or the optimum orientation of the robot for the welding process can be defined, for example. A big advantage of the new software, according to Ritter, is export possibilities. Integrators, he adds, will benefit from the ability to export the simulation as a 3D PDF, which can be simply opened with an Acrobat Reader.

Detailed information in 2D for mechanical commissioning can also be provided via the export feature. One of the highlights of this is product presentation using a virtual reality headset. Tablets and smartphones also deliver impressive simulation results on the go via the Mobile Viewer app, informs Ritter. Signing a major contract with Daimler to supply four-figure number of robots and linear units (KR Fortec and KR Quantec), and other Kuka technologies such as software and controllers, the company has maintained a positive outlook despite Covid-19. Working towards strengthening its position as a global player, Kuka is driving the goal of making automation available to everyone. Looking at conquering new areas and new markets, it is stressing on the potential for cobots – sensitive robots – in the auto industry.

- SIAM

- Society of Indian Automobile Manufacturers

- Enhancing Efficiencies in Automotive Logistics

- Tapan Ghosh

SIAM Conclave Highlights Push for Sustainable Logistics in Indian Auto Sector

- By MT Bureau

- July 18, 2025

The Society of Indian Automobile Manufacturers (SIAM) convened its 11th Automotive Logistics Conclave today in New Delhi, spotlighting the shift toward more efficient and sustainable logistics in India’s fast-growing automotive sector.

Centred around the theme 'Enhancing Efficiencies in Automotive Logistics,' the event brought together key government officials, automotive leaders, and logistics service providers to deliberate strategies for building a resilient and eco-conscious logistics ecosystem.

Senior Railway Board official Hitendra Malhotra announced the introduction of specialised, higher-capacity railway wagons, including double-deck options tailored for SUVs, supporting increased vehicle transport needs.

Tapan Ghosh, Chairman of the SIAM Logistics Group and VP at Hyundai Motor India, noted that the sector has witnessed a 7.3% growth in FY 2024–25, attributing part of this expansion to enhanced logistics capabilities. Industry players highlighted a growing reliance on digital innovation, multimodal transport solutions, and rail-based logistics to increase efficiency and reduce carbon footprint.

S D Chhabra of Maruti Suzuki emphasised the integration of real-time tracking technologies and a broader push toward sustainability. Policy alignment and infrastructure development were also key focal points, with participation from leading firms including Mahindra & Mahindra, Ashok Leyland, Chetak Logistics, and APLL VASCOR.

The conclave reinforced SIAM’s commitment to green mobility, with discussions calling for industry-wide adoption of eco-friendly practices and regulatory coherence aligned with India's national sustainability goals.

Several logistics providers were recognised at the event for excellence in innovation and operations, underscoring the sector’s critical role in shaping the future of Indian mobility.

- Indian Racing League 2025

- IRL 2025

- Raoul Hyman

- Fabienne Wohlwend

- Laura Camps Torras

- Cailin Wood

- Ruhaan Alva

- Le Mans

- Neel Jani

- GP2

- Jon Lancaster

- Arjun Kapoor

- Naga Chaitanya

- John Abraham

- Sourav Ganguly

- Sudeep Kichcha

- Keerthivasan

- Akhilesh Reddy

Indian Racing League 2025 Kicks Off With First-Ever Driver Draft In Mumbai

- By MT Bureau

- July 15, 2025

The Indian Racing League (IRL) formally launched its 2025 season with a driver draft event held in Mumbai. This marked the first time a driver draft format was used in Indian motorsport, featuring the selection of 24 drivers across 6 city-based franchises, including international racers, Indian talent and women drivers.

Each team picked four drivers based on a fixed structure: one international driver, one emerging Indian or international talent, one Indian domestic racer and one female driver. Among the key names drafted were Le Mans winner Neel Jani, GP2 veteran Jon Lancaster, IRL champion Raoul Hyman and young Indian racers Ruhaan Alva, Sohil Shah and Akshay Bohra. Women racers such as Caitlin Wood, Fabienne Wohlwend and Laura Camps Torras also joined the grid, bringing diverse experience from series like the W Series, GT racing and F4.

The event also featured a joint press conference with all six team owners — including Arjun Kapoor, Naga Chaitanya, John Abraham, Sourav Ganguly, Sudeep Kichcha and Keerthivasan — who introduced their teams and outlined their plans for the season. Racing Promotions (RPPL) Chairman Akhilesh Reddy stated that the draft aimed to bring greater structure and inclusivity to Indian motorsport. The 2025 IRL season begins in August and will be held across city circuits and racetracks throughout India.

Auto Retail Grows 5% In June, FADA Maintains Cautious Optimism For Near-Term

- By MT Bureau

- July 07, 2025

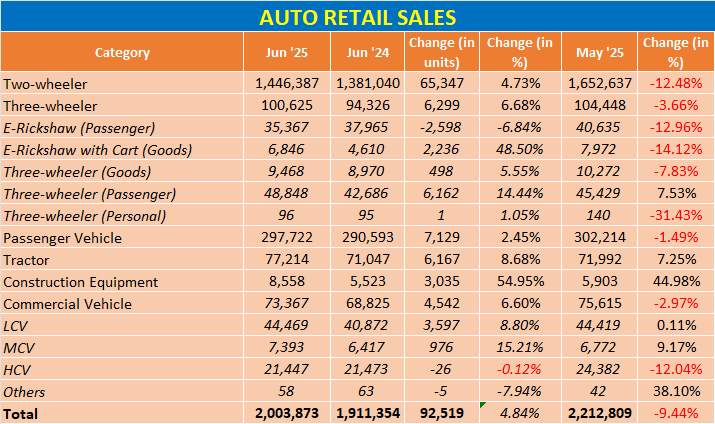

The Federation of Automobile Dealers Association (FADA), the apex body representing automotive dealerships in the country, has released the retail sales data for June 2025, which saw a total of 2 million vehicles sold in the country, which was 4.84 percent higher YoY, but 9.4 percent lower than the previous month.

Last month, two-wheeler sales continued to be in the green with 1.44 million units sold, as against 1.38 million units sold last year. Three-wheeler sales grew by 6.6 percent, while passenger vehicle sales at 297,722 units, saw a flattish growth of 2.45 percent YoY. Tractor sales at 8.6 percent, construction equipment at 54.95 percent and commercial vehicle with 6.6 percent showed signs of healthy growth.

C S Vigneshwar, President, FADA, said, “While two-wheelers showed some early-cycle softness, we remain confident of a robust ramp-up in the coming months as seasonal demand and targeted OEM initiatives take effect.”

He pointed out that while festival and marriage-season demand provided a boost, financing constraints and intermittent variant shortages moderated sales. Early monsoon rains and rising EV penetration also shaped buying patterns in the two-wheeler segment.

“Several dealers cited compulsory billing and forced stock lifts – often via auto-debit wholesales – leading to mandated high days of inventory aligned with festival-season targets. Overall, June demonstrated a resilient two-wheeler performance amid mixed market signals,” he noted.

In the passenger vehicle space despite elevated incentive schemes and fresh booking lent support, heavy rains and tight market liquidity impacted sales. “Some dealers indicated that certain PV OEMs have introduced compulsory billing procedures – such as automatic wholesale debits – to meet volume targets; inventory consequently stands at around 55 days. June thus painted a picture of modest but steadfast PV performance amid varied market cues,” Vigneshwar said.

The CV segment saw early-month deliveries buoy volumes before monsoon-induced slowdowns and constrained liquidity dampened inquiries and conversions. The impact of new CV taxation along with mandatory air-conditioned cabins has elevated ownership cost, alongside muted infrastructure demand.

Cautious optimism

Looking ahead, the retail body anticipates a period of mixed fortunes. Above-average monsoon rains in July, are expected to boost rural demand, particularly for two-wheelers, thanks to stronger farm incomes highlighted by an 11.3 percent YoY increase in Kharif sowing. However, intense rainfall in some regions could create logistical challenges.

Simultaneously, substantial government capital expenditure from June to August on infrastructure projects like roads, railways, metros and green energy initiatives will continue to support the CV and CE segments.

Despite these positive drivers, several headwinds remain. Evolving geopolitical tensions and potential repercussions from US tariff measures necessitate careful supplychain management and could dampen consumer confidence. Furthermore, scarcity of rare-earth materials is hindering component production, which in turn limits overall supply and retail volumes.

In the two-wheeler market, early monsoon showers and renewed rural activity have sparked interest, but heavy rainfall, component shortages and price hikes effective this month are impacting conversions. Passenger vehicles face challenges from high-base effects, a limited number of new model launches and tight financing, although festival planning and new incentive schemes offer some counterbalance. Commercial vehicles continue to contend with subdued infrastructure demand, increased ownership costs due to new taxes and mandatory air-conditioned cabin regulations, though extended order pipelines provide some relief.

Vigneshwar expects that July is likely to see a blend of agrarian tailwinds and the positive impact of school reopenings, tempered by seasonal difficulties, higher prices and liquidity constraints.

Tata Motors’ PV And CV Sales In The Negative, Outlook Remains Positive

- By MT Bureau

- July 01, 2025

Tata Motors, one of the leading passenger vehicle and commercial vehicle manufacturers in the country, has announced its wholesales for June 2025 and Q1 FY2026.

The company reported that its total PV sales came at 124,809 units in Q1 FY2026, down 10 percent from Q1 FY2025 on a YoY basis. Domestic PV sales, including EVs, came at 123,839 units, down 10 percent YoY. For June, PV sales came at 37,083 units, down 15 percent compared to the same period last year.

| TATA MOTORS PASSENGER VEHICLES | ||||||

| June '25 | June '24 | Change (in %) | Q1 '26 | Q1 '25 | Change (in %) | |

| PV Domestic (includes EV) | 37,083 | 43,524 | -15% | 123,839 | 138,104 | -10% |

| PV IB | 154 | 100 | 54% | 970 | 578 | 68% |

| Total PV (includes EV) | 37,237 | 43,624 | -15% | 124,809 | 138,682 | -10% |

| EV (IB + Domestic) | 5,228 | 4,657 | 12% | 16,231 | 16,579 | -2% |

Shailesh Chandra, Managing Director, Tata Motors Passenger Vehicles and Tata Passenger Electric Mobility, said, “In Q1 FY2026, the passenger vehicle industry experienced volume pressures, particularly in May and June, with flat growth reflecting continued softness in demand."

"The electric vehicle segment emerged a bright spot, driven by robust growth and the launch of new EV models across OEMs, enhancing customer interest and consideration. Tata Motors reported wholesales of 124,809 units in Q1 FY2026, including 16,231 EV units, underscoring our commitment to aligning wholesale and registration volumes. EV sales gained strong momentum towards the end of the quarter with a healthy growth trajectory. The refreshed Tiago posted 16 percent YoY volume growth in Q1 FY2026 and new launches – Altroz and Harrier.ev – saw a positive market response, with their full impact expected in the coming months,” he said.

On the other hand, Tata Motors’ commercial vehicle (CV) business reported sales of 85,606 units, down 6 percent YoY for Q1 FY2026. Domestic CV sales at 79,572 units, were down 9 percent as compared to Q1 FY2025.

In June 2025 alone, total CV sales came at 30,238 units, which is 5 percent lower than June 2024. In the domestic market, the demand for Medium and Heavy Commercial Vehicles (MH&ICV) came at 12,871 units, as against 4,640 units for the same period last year. During Q1 FY26, MH&ICV domestic sales were 37,370 units as against 40,349 units in Q1 FY25.

| TATA MOTORS COMMERCIAL VEHICLES | ||||||

| June '25 | June '24 | Change (in %) | Q1 '26 | Q1 '25 | Change (in %) | |

| HCV Trucks | 7,359 | 8,891 | -17% | 21,735 | 24,690 | -12% |

| ILMCV Trucks | 4,863 | 4,997 | -20% | 14,497 | 13,791 | -20% |

| Passenger Carriers | 5,658 | 5,654 | 4% | 15,089 | 14,893 | 9% |

| SCV Cargo & Pickup | 10,056 | 11,081 | 1% | 28,251 | 34,241 | 4% |

| Total CV Domestic | 27,936 | 30,623 | -9% | 79,572 | 87,615 | -9% |

Girish Wagh, Executive Director, Tata Motors, said, “Q1 FY26 began on a subdued note for the commercial vehicle industry with muted performance in the HCV and SCVPU segments while buses, vans and ILMCVs registered modest year-on-year growth. Tata Motors Commercial Vehicles recorded domestic sales of 79,572 units, 9.2 percent decline compared to Q1 FY25."

"However, June 2025 witnessed a sequential growth of 8 percent over May 2025. Additionally, our International Business delivered a robust 67.9 percent growth in volumes over Q1 FY25. During the quarter, we launched India’s most affordable mini-truck, the Ace Pro, offered in petrol, bi-fuel and electric powertrains, which received an encouraging market response. We enhanced driver comfort by introducing air-conditioned cabins across our entire range of light to heavy trucks. We also expanded our international footprint by entering Egypt and expanded our offerings for the Middle East North African region,” Wagh added.

Going forward, Wagh stated that with forecasts for a healthy monsoon across the country, a reduction in repo rate and renewed thrust on infrastructure development, will bring back sales momentum for the commercial vehicles segment.

Chandra too shared his optimism for the PV market and stated, “Looking ahead, while overall industry growth is expected to remain subdued, Tata Motors is well positioned to leverage its new launches to outperform across segments—including hatchbacks and SUVs, while continuing to build on the EV momentum.”

Comments (0)

ADD COMMENT