- Society of Indian Automobile Manufacturers

- SIAM

- Shailesh Chandra

- Rajesh Menon

- auto wholesales

- sales

- car sales

- bike sales

- scooter sales

- truck sales

- bus sales

- three-wheeler sales

- SUVs

- passenger cars

PVs, CVs wholesales in the red for Q2 FY2025, 2Ws and 3Ws power overall growth

- By MT Bureau

- October 14, 2024

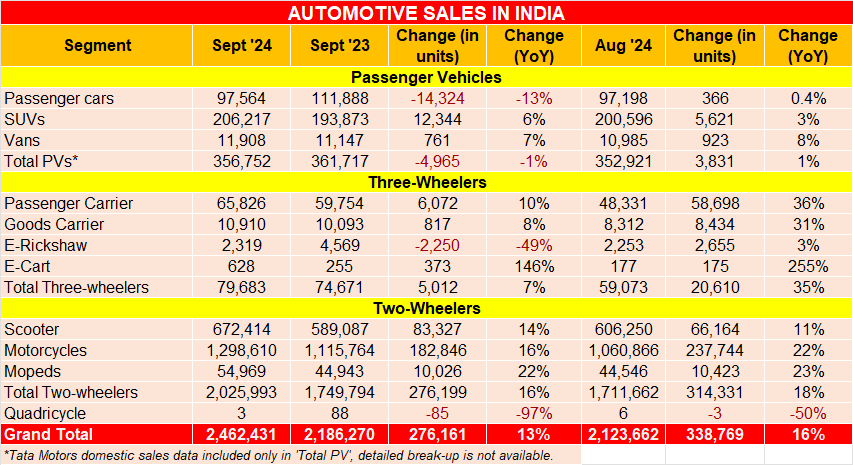

The automotive wholesales numbers for September 2024 and Q2 FY2025 are out, seeing mixed results.

As per the latest data released by the Society of Indian Automobile Manufacturers (SIAM), the apex body representing automakers in India, for September 2024, the passenger vehicle segment sold 356,752 which was down 1 percent YoY compared to 361,717 units sold last year.

On the other hand, the three- and two-wheeler segments continued to power the overall sales with 79,683 units and 2,025,993 units, seeing 7 percent and 16 percent growth respectively. This translates to a total of 2,462,431 vehicles sold in September, up 13 percent, compared to 2,186,270 units sold last year.

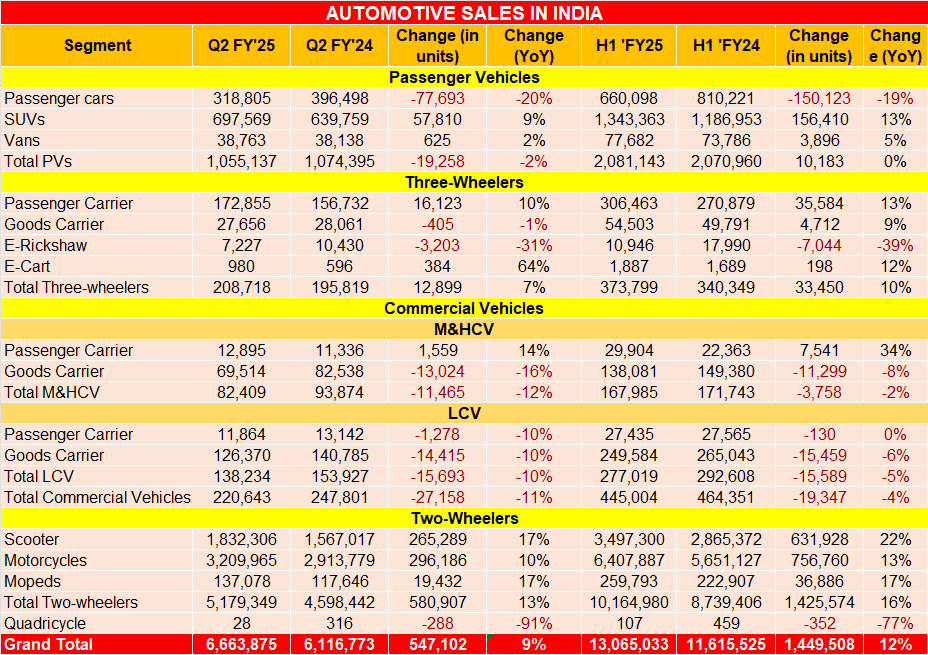

Similarly, in Q2 FY2025, a total of 6,663,875 vehicles were sold, registering a 9 percent growth YoY, as compared to 6,116,773 units sold last year.

Of this, passenger vehicle sales declined by 2 percent at 1,055,137 units; commercial vehicles barring buses were all in the red. A total of 220,643 commercial vehicles were sold, registering a decline of 11 percent YoY, as compared to 247,801 units sold last year.

The three-wheeler and two-wheeler segments continued to be the bright spot with sales of 208,718 units (7% YoY) and 5,179,349 units (13% YoY) respectively.

Shailesh Chandra, President, SIAM said, “The overall Indian automobile industry remained strong in Q2 2024-25 with 8.9 percent growth compared to Q2 2023-24. Two- and Three-Wheelers continued to post strong growth of 12.6 percent and 6.6 percent respectively, while passenger vehicles and commercial vehicles posted some degrowth in Q2 of 2024-25 compared to 2023-24. Heavy rainfall in key states and almost the entire ‘Shradh’ period falling in the month of September, did impact the sales numbers of some of the segments. With the rains easing and continued infrastructure spending, and the arrival of the festive season boosting consumption, we anticipate healthy demand in the next quarter.”

Rajesh Menon, Director General, SIAM said, “Although passenger vehicle segment de-grew by 1.8 percent in Q2 of 2024-25 as compared to Q2 of last year, for the 3rd time it crossed the 1 million mark in Q2, posting a sales of 1.06 million units. Two-wheelers posted sales of 5.18 million units in Q2 for FY 24-25 as compared 4.60 million units in Q2 of last year. Three-wheelers posted the highest ever sales of Q2 with 2.09 lakh units. Commercial vehicles posted a degrowth of 11 percent in Q2 of 2024-25 as compared to Q2 of last year, with sales of 2.21 lakh units.”

Nissan To Shut Oppama Plant In Japan, Shift Production To Kyushu Facility As Part Of Restructuring Plan

- By MT Bureau

- July 16, 2025

Japanese automaker Nissan Motor Co., which has been undertaking significant measures to improve its financial performance and is restructuring global operations, has announced that it plans to transfer and integrate vehicle production at the Oppama Plant, located in the Oppama district, to Nissan Motor Kyushu Co., Ltd in Fukuoka Prefecture.

This move part of the ‘Re:Nissan’ recovery plan aims to reduce its global production capacity from 3.5 million units (excluding China) to 2.5 million units, while maintaining a plant utilisation rate of around 100 percent. To achieve this, the company has been considering the consolidation of production sites from 17 to 10.

Nissan Reiterates Commitment For India, Targets 200,000 Unit Sales For FY2026

The new announcement will see vehicle production shutting down at Nissan’s Oppama plant at the end of fiscal 2027. Following this, both current and future models scheduled for production at Oppama will be manufactured at Nissan Motor Kyushu.

On the other hand, facilities and functions in the district – such as the Nissan Research Center, Grandrive, the crash test facility and Oppama Wharf – will remain unaffected and continue operations as usual.

Ivan Espinosa, CEO, Nissan Motor Co, said, "Today, Nissan made a tough but necessary decision. It wasn’t easy – for me or for the company – but I believe it’s a vital step toward overcoming our current challenges and building a sustainable future. The Oppama Plant is a proud part of our history, and its legacy will endure. I want to sincerely thank our employees, the local community, and our partners who have supported this plant with dedication and heart. We will continue to operate in the Oppama area with strong support for the local community, as we carry forward the spirit of Oppama plant and work to restore Nissan’s true value."

While the company has announced the shutdown of manufacturing operations at the Oppama plant, it is still exploring a ‘wide range of options to determine the most appropriate path forward’.

The company will continue to retain employees at the plant till the end of fiscal 2027 and is looking to initiate discussions with the union on the future course of action.

Furthermore, the Japanese automaker has also announced that production of the NV200, currently consigned to the Nissan Shatai Shonan Plant, will end in fiscal year 2026. A successor to the NV200 is planned for introduction in fiscal year 2027, with further details to be shared at a later date.

With this decision, Nissan said it has concluded all vehicle production consolidation actions in Japan under the Re:Nissan plan.

Also read: Nissan Secures $6 Billion Through Bond Issuance

- Skoda Auto Volkswagen India

- Skoda India

- Octavia

- Laura

- Superb

- Kodiaq

- Kushaq

- Slavia

- Kylaq

- Andreas Dick

- Piyush Arora

Skoda Auto Volkswagen Rolls Out 500,000th Made In India Skoda Car

- By MT Bureau

- July 04, 2025

Skoda Auto Volkswagen India has announced that it has achieved a major manufacturing milestone in its operations. The company recently rolled out its 500,000th made-in-India Skoda vehicle.

The milestone comes after 24 years since the company introduced the first Skoda Octavia from its Chhatrapati Sambhaji Nagar facility (formerly Aurangabad) in 2001.

At present, the company manufactures vehicles across two facilities in India – Chhatrapati Sambhaji Nagar and Pune, with them now supporting the company’s new manufacturing plant in Vietnam with parts and components.

Over the years, Skoda has rolled out its iconic products such as Octavia, Laura, Superb and Kodiaq to new products like the Kushaq, Slavia and its first sub-4-meter Kylaq.

Andreas Dick, Board Member for Production and Logistics, Skoda Auto, said, “Reaching the milestone of 500,000 cars produced in India is a proud testament to our strategic vision of unwavering commitment to India and operational excellence. By nurturing local engineering talent and embedding global manufacturing processes, we’ve built an ecosystem that is agile, scalable, and responsive to a dynamically changing environment that meets the highest international standards. This achievement reflects the synergy between world-class innovation and India’s growing industrial prowess.”

Piyush Arora, CEO & Managing Director, Skoda Auto Volkswagen India, said, “It is not just about manufacturing 500,000 cars, but building and nurturing 500,000 connections. Every car that rolls out of our production lines, shares DNA of European engineering with unmatched quality, crafted with precision; delivering supreme comfort, safety, technology and driving dynamics. This achievement belongs as much to our customers as it does to our employees. Because what we’re manufacturing here isn’t just mobility, it’s a belief in what India can make for domestic as well as international markets. India plays a pivotal role in the Group’s growth strategy. I am glad to mention that we achieve this manufacturing milestone in the same year as Skoda Auto celebrates 130 years of legacy globally and 25 years of presence in India.”

The company revealed that approximately 70 percent of the vehicles manufactured in India were rolled out from its Chhatrapati Sambhaji Nagar plant.

Shell Lubricants Acquires Raj Petro From Brenntag Group To Further Expand Lubricants Business

- By MT Bureau

- July 03, 2025

Shell Lubricants, the lubricants business of UK-headquartered Shell Group of companies, has acquired 100 percent equity stake in Raj Petro Specialities from Brenntag Group.

India is currently the world’s third-largest lubricant market and this initiative Shell expects to further expand its portfolio and customer base in the country, but also enhance its presence in the global markets.

Raj Petro is a multi-faceted petrochemical manufacturing and marketing company with business partners in about 100 countries across the globe and offers a wide range of products catering to power, energy, transport, construction, automotive, personal care, food, agriculture, pharmaceutical and other industries.

The acquisition of Raj Petro Specialities supports Shell Lubricants as it strives to grow its portfolio and customer base in India, which is one of its key growth markets.

Jason Wong, Executive Vice-President for Global Lubricants, Shell, said, “The addition of Raj Petro Specialities will help maximise value for Shell through a complementary product portfolio and increased scale of business, positioning Shell Lubricants for further growth in line with our unwavering focus on performance, discipline, and simplification.”

- SSAB

- Polmotors

- fossil-free materials

- decarbonised steel

- Vattenfall

- LKAB

- Volkswagen

- Audi

- BMW

- Peugeot

- Citroen

- Jeep

- Stellantis

- Mercedes-Benz

- Opel

- Maciej Grabos

- Robert Lewandowski

SSAB Partners Polmotors To Introduce Fossil-Free Steel Structural Automotive Components

- By MT Bureau

- June 27, 2025

Swedish steel manufacturer SSAB has announced a new collaboration with Polmotors, a tier 1 supplier focusing on low-emission products, for exploring the potential of fossil-free materials in demanding automotive applications.

The partnership will see Polmotors explore manufacturing components using SSAB’s decarbonised steel.

SSAB is working on two unique decarbonised steels and aims to largely eliminate carbon dioxide emissions from its own operations. It has already introduced SSAB Zero, which is based on recycled steel and made using fossil-free energy. The company claims that it has also successfully produced the world’s first fossil-free steel. It works with iron ore producer LKAB and energy company Vattenfall as part of the HYBRIT initiative to develop a value chain for fossil-free iron- and steel production, replacing the coking coal traditionally used for iron ore-based steelmaking with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxide emissions in steel production.

On the other hand, Polmotors closely works with the likes of Volkswagen, Audi, BMW, Peugeot, Citroen, Jeep, Stellantis, Mercedes-Benz and Opel among others, to introduce high-performance components which are not only lighter but also greener.

Maciej Grabos, CEO, Polmotors, said, “Polmotors sees the future of fossil-free steel. And the potential competitive advantage of being an early adopter, positioning ourselves to meet the anticipated market demand from premium automotive OEMs. We design and manufacture crash management systems (CMSs) for these customers, such as bumpers and rally bars, so choice of materials is crucial. Polmotors looks forward to joint R&D – working with SSAB and the OEMs – for the implementation of new steel grades in our products.”

Robert Lewandowski, Key Account Manager, SSAB, said, “Polmotors recently celebrated its 35thanniversary. I’ve had the pleasure and privilege to meet them 20 years ago and observe how an initially small, Polish-owned enterprise turned into a global Tier1 supplier. Decarbonisation of the automotive industry requires cooperation across the supply chain where Tier 1 companies play an important role”.

Comments (0)

ADD COMMENT