Capitalising on the demand for luxury cars in the Indian market, Mercedes Benz India has launched the CKD version of its flagship sedan, the S-Class, in India.

The 2021 S-Class has been an instant hit for the company, as it sold 150 CBU units allotted for India within a few months of its launch. Making the deal even sweeter for its customers, Mercedes Benz has decided to offer a locally assembled model of the S-Class. The flagship car will be made at the company’s facility at Chakan, Pune. The earlier models of the S-Class were also produced at the same facility.

The company has adopted a digitised production process to keep a tab on the quality and process history. The production process consists of shop floor dashboards, digital job cards, holo-lens, and other connected technologies.

For the CKD route Mercedes has replaced the S400d with the S350d while the S450 4Matic continues as the petrol model. The S350d is powered by a 2925 cc diesel engine producing 286 hp and 600 Nm of torque, while the S450 4Matic is equipped with a 2999 cc petrol motor with a hybrid unit. The S450 has a combined power output of 391 hp and total torque exceeding 750 Nm. The standard 9G-Tronic gearbox handles transmission duties on both variants.

The CKD S-Class is launched at INR 15.7 million for the S 350d variant and INR 16.2 million for the S450 variant. In comparison to the CBU S-Class models, the locally assembled product has brought the cost down for the diesel variant by INR 6 million while the petrol model has got dearer by INR 5.8 million.

Highlights of the 2021 S-Class includes a 12.8-inch central touchscreen with MBUX system, rear-seat entertainment screens with OTT content display, massage functionalities on all seats, air purification and fragrance systems, functional ambient lighting, leather upholstery in three colours, among others. The car comes fully equipped with three radars for ADAS functionality. (MT)

Mahindra Reports Consolidated PAT Of INR 46.75 Billion For Q3 FY2026

- By MT Bureau

- February 11, 2026

Mumbai-headquartered automotive major Mahindra & Mahindra (M&M) has announced its financial results for Q3 FY2026, reporting a consolidated Profit After Tax (PAT) of INR 46.75 billion, representing a 54 percent YoY growth.

The automotive division recorded quarterly volumes of 302,000 units, up 23 percent YoY. SUV revenue market share rose by 90 bps to 24.1 percent. The automotive business reported consolidated revenue of INR 303 billion, up 30 percent YoY, while PAT stood at INR 19.93 billion, up 42 percent YoY.

In the farm sector, tractor volumes reached 150,000 units, up 23 percent YoY, which translates to a market share of 44 percent for Q3. The revenue came at INR 115 billion, up 21 percent YoY, while PAT came at INR 10 billion, up 7 percent YoY.

Dr. Anish Shah, Group CEO & Managing Director, said, “We are delighted to report solid operating performance across the group in Q3’F26, reflecting our strong focus on growth coupled with disciplined execution. Auto & Farm has maintained its leadership position on the back of steady customer demand, strong product acceptance and unwavering focus on operational excellence. TechM continues to make meaningful progress. Mahindra Finance delivered another solid quarter with meaningful PAT growth while maintaining strong asset quality. We are especially pleased to see breakout performance from two of our growth gems, Mahindra Logistics and Mahindra Lifespaces.”

Rajesh Jejurikar, Executive Director & CEO (Auto and Farm Sector), said, “Auto and Farm businesses delivered strong performance in Q3’FY26. We have achieved a 90 bps YoY increase in SUV revenue share and 10 bps YoY increase in LCV (< 3.5T) market share in Q3. Our tractor business gained 20 bps YoY to reach an impressive 44.1 percent share for YTD FY26. Our new launches XEV 9S, and the XUV 7XO have received very positive response in the market.”

Amarjyoti Barua, Group Chief Financial Officer, added. “Our Q3 consolidated results reflects the strength and depth of our diversified portfolio. Our services businesses continue to increase their contribution to the overall results. Our results are also translating into a very strong Balance Sheet.”

- CEER

- Saudi Arabia

- Abdul Latif Jameel

- Zamil Trade & Services

- Zamil Plastics

- NSSPC

- KK Nag

- Mino

- FEV

- AVL

- MK Tron

- XYG

- Sika

- AITS

- FPI

- James DeLuca

CEER Inks 16 Agreements Worth USD 996 Million To Expand Saudi EV Supply Chain

- By MT Bureau

- February 10, 2026

CEER, Saudi Arabia’s first electric vehicle (EV) brand and Original Equipment Manufacturer (OEM), has signed 16 commercial agreements valued at over SAR 3.7 billion (USD 996.90 million). The deals were announced at the 4th PIF Private Sector Forum, following SAR 5.5 billion (USD 1.4 billion) in agreements secured at the previous year's event.

The partnerships are part of a localisation strategy that aims to source 45 percent of vehicle materials and components from Saudi companies by 2034. The supply chain will support CEER’s production plan of seven models over the next five years.

The agreements cover a range of essential automotive components and services:

- Fluids and Plastics: Abdul Latif Jameel (ALJ) will supply windshield washer fluid and EV coolants. Zamil Trade & Services and Zamil Plastics will provide brake fluids and aerodynamic covers.

- Materials and Polymers: NSSPC is contracted for PP resin and polymer compounds, while KK Nag will provide Expanded Polypropylene (EPP).

- Engineering and Infrastructure: Mino will install steel Body Shop equipment. FEV and AVL will provide engineering services.

- Manufacturing: MK Tron will produce small stampings, window regulators, and door hinges. FPI will supply front-end modules and XYG will provide glazing solutions.

- Chemicals and HVAC: Sika is contracted for structural adhesives and cavity baffles, while AITS will work on HVAC localisation.

The project is expected to contribute SAR 30 billion (USD 8 billion) to Saudi GDP by 2034 and improve the trade balance by SAR 79 billion (USD 21 billion). CEER estimates the creation of 30,000 direct and indirect jobs, aligning with the industrial diversification goals of Saudi Vision 2030.

James DeLuca, CEO, CEER, said, “These agreements are a cornerstone of CEER's wide and deep localisation strategy, which targets sourcing 45 percent of vehicle materials and components from Saudi companies by 2034. Our approach goes beyond mere assembly, we are utilising local raw materials and empowering Saudi companies to become global suppliers, directly contributing to Vision 2030’s mission to diversify the national automotive industry and drive sustainable economic growth.”

“These agreements represent a major step in building a comprehensive automotive ecosystem in the Kingdom. By using local materials and resources, attracting advanced technology and foreign investment, and localising the production of heavy and labour-intensive components, we aim to reduce CO2 emissions and create meaningful job opportunities for Saudi nationals,” added DeLuca.

Cars24 Introduces Refreshed Brand Identity

- By MT Bureau

- February 09, 2026

Cars24 has unveiled a refreshed brand identity, moving from its original transactional focus towards a car ownership ecosystem.

Founded in 2015, the company originally utilised an all-caps logo – CARS24 – to establish a presence in a fragmented market. The updated identity shifts the name to sentence case, Cars24, which the company states reflects maturity and a focus on trust.

The core of the redesign features an open circular logo. According to the company, this form represents the continuity of car ownership, where vehicles change hands and user needs evolve. The open shape is intended to signal flexibility rather than closure.

The brand has also replaced its traditional blue with a brighter shade. This ‘younger blue’ is intended to make the brand appear more attentive and human as it scales its operations.

The identity update was the result of over 1,200 hours of design and iteration. The goal of the project was to create a look that remains relevant as the company expands its services beyond buying and selling into broader ownership systems.

Vikram Chopra, Founder & CEO, Cars24, said, “When we started, being loud helped. But as the company and the team grew up, the work started speaking for itself. This change is about reflecting who we are today, calmer, more human and focused on earning trust over time.”

Maruti Suzuki India Increases Rail Dispatches To 585,000 Units, Up 18% In 2025

- By MT Bureau

- February 09, 2026

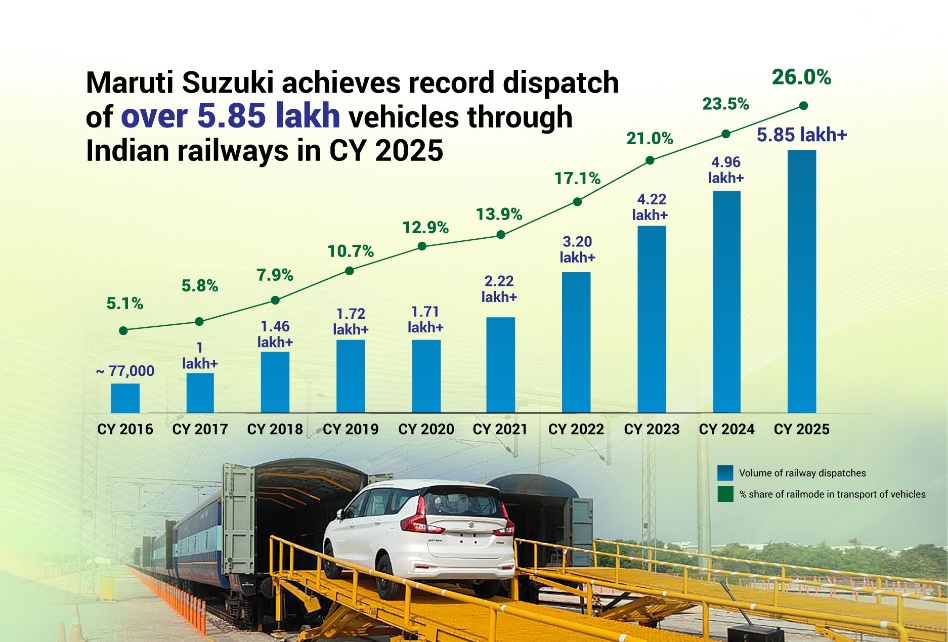

Maruti Suzuki India, the country’s largest passenger vehicle manufacturer, has reported the dispatch of over 585,000 vehicles using the railway network in CY2025, which marked an 18 percent growth compared to CY2024.

Over the last decade, the company's use of rail for outbound logistics has risen from 5.1 percent in 2016 to approximately 26 percent in 2025. The shift aims to reduce carbon emissions, oil imports and road congestion.

In 2025, Maruti Suzuki India inaugurated an in-plant railway siding at its Manesar facility. The company also became the first manufacturer to dispatch vehicles to the Kashmir valley using the railway bridge over the Chenab river.

Combined dispatches from in-plant sidings at Gujarat and Manesar accounted for 53 percent of the company's total rail volumes during the year. The manufacturer currently employs 45 flexi-deck rakes, with each train capable of transporting approximately 260 vehicles.

Combined dispatches from in-plant sidings at Gujarat and Manesar accounted for 53 percent of the company's total rail volumes during the year. The manufacturer currently employs 45 flexi-deck rakes, with each train capable of transporting approximately 260 vehicles.

The company was the first automaker to receive an Automobile-Freight-Train-Operator (AFTO) license in 2013. Since FY2014-15, it has transported more than 2.8 million vehicles to 600 cities using a hub-and-spoke model.

Hisashi Takeuchi, MD & CEO, Maruti Suzuki India, said, “The year 2025 marks our highest-ever rail dispatch, with over 585,000 units. During the year, we strengthened our green logistic efforts through two landmark events – the inauguration of India’s largest automobile in-plant railway siding at our Manesar facility and second was we dispatched vehicles by rail to Kashmir valley through the world's highest railway arch bridge over Chenab river, a first by any automobile manufacturer. Our mid-term goal is to increase rail-based vehicle dispatches to 35 percent by FY 2030-31, contributing to India’s net-zero ambition by 2070. Maruti Suzuki India has adopted a comprehensive ‘Circular Mobility’ approach to sustainability, aiming to reduce its carbon footprint across the entire vehicle lifecycle – from design and production to logistics and end-of-life vehicle (ELV) management.”

Comments (0)

ADD COMMENT