- Honda Motorcycle & Scooter India

- HMSI

- Honda Motor Co

- Toshihiro Mibe

- electrification

- ADAS

- Nissan

- Mitsubishi Motors

Honda Reassesses Electrification Strategy Amid Shifting Global Market Dynamics

- By Nilesh Wadhwa

- May 20, 2025

Japanese automotive major Honda Motor Co, has announced a strategic realignment of its electrification roadmap, responding to evolving global market conditions and regulatory landscapes.

In a recent business briefing, Toshihiro Mibe, Director, President and Representative Executive Officer (Global CEO), emphasised on the company's commitment to achieving carbon neutrality and zero traffic fatalities by 2050, while adapting to current challenges.

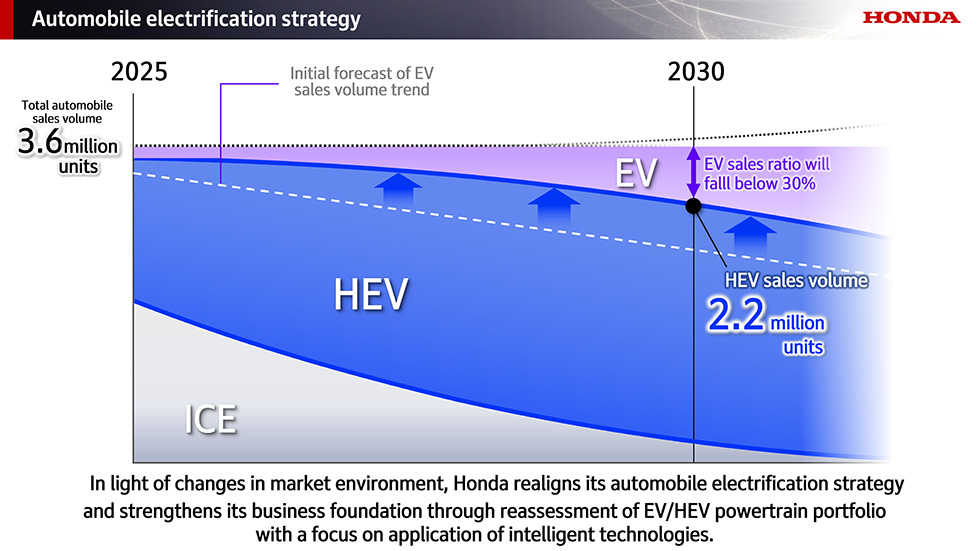

He reiterated that Honda's initial target to achieve 100 percent global sales of electric vehicles (EVs) and fuel cell electric vehicles (FCEVs) by 2040 remains unchanged. However, the company acknowledges a slower-than-anticipated adoption of EVs, particularly in the United States and Europe, due to relaxed environmental regulations and market uncertainties.

Conversely, hybrid-electric vehicles (HEVs) are experiencing increased demand, offering a practical solution for reducing CO2 emissions without the immediate need for extensive charging infrastructure.

Two-pronged strategy

To navigate these shifts, Honda has outlined two primary strategic directions:

-

Enhancing EV and HEV Competitiveness: Honda aims to integrate intelligent technologies into its EV and HEV models, focusing on advanced driver assistance systems (ADAS) and connected services to deliver new value to customers.

- Reassessing Powertrain Portfolio: The company plans to diversify its powertrain offerings, balancing the development of EVs, HEVs and internal combustion engine (ICE) vehicles to meet varying regional demands and regulatory requirements.

Recognising the scale of investment required for electrification and intelligent technologies, Honda is exploring strategic partnerships, including ongoing discussions with Nissan and Mitsubishi Motors. While a full business integration is not currently planned, these collaborations aim to strengthen shared technological capabilities and market presence.

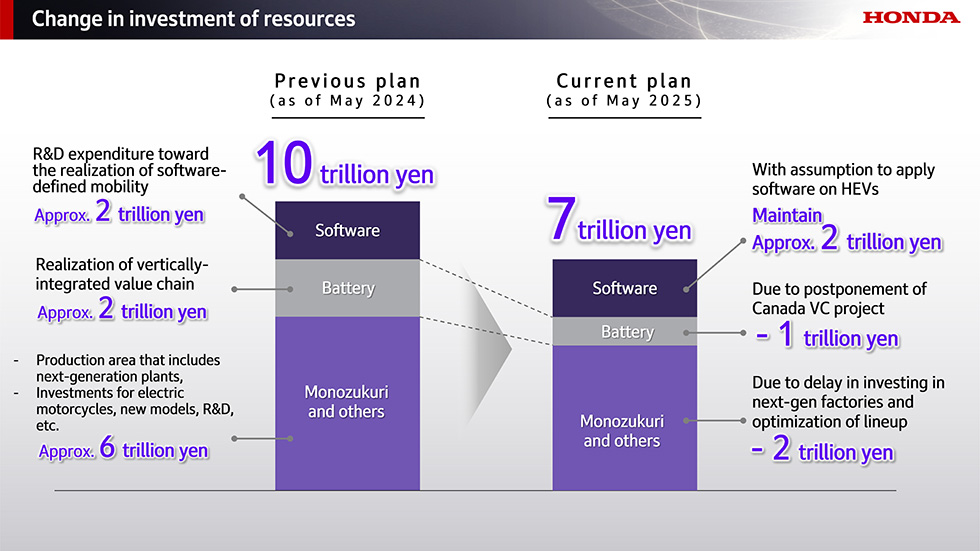

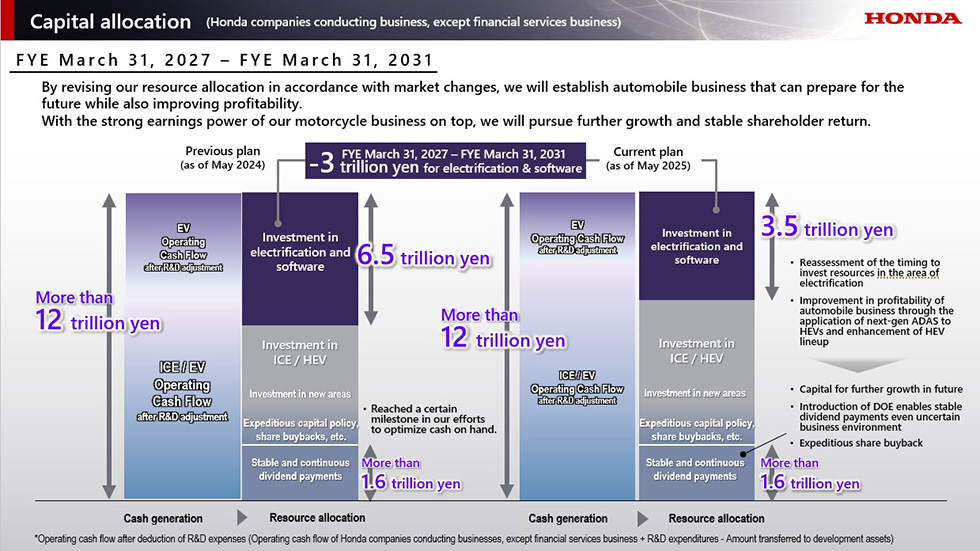

The Japanese automaker which had announced an ambitious plan to invest 10 trillion YEN towards establishing a robust EV value chain, exemplified by its planned battery-focused project in Canada. Now, the company has revised the CAPEX to 7 trillion YEN till 31 March 2031.

“As for EVs, due to the recent market slowdown, our EV sales ratio in 2030 is now expected to fall below the previously announced target of 30 percent. On the other hand, the demand for HEV models is high. Therefore, we will position our HEVs, mostly next-generation HEV models which we will introduce in 2027 onward, as a group of products that will play a key role during the transition period towards the popularisation of EVs,” said Mibe.

The company targets total automobile sales volume of 3.6 million units, with a HEV sales target of 2.2 million units by 2030.

Two-wheeler sales

Honda Motor Co. announced that its global two-wheeler sales reached a record 20.57 million units for the FY2025, capturing approximately 40 percent of the global two-wheeler market. The company set new all-time sales records in 37 countries and territories, reinforcing its leadership position in the two-wheeler segment.

Looking ahead, Honda expects continued growth in global motorcycle demand, particularly across the Global South, with India – a key market with a growing population and rising income levels – at the forefront. Industry-wide sales are projected to increase from the current 50 million units to approximately 60 million by 2030.

To capitalise on this growth, Honda plans to introduce a broader range of two-wheelers tailored to the varied needs of global customers. It will also optimise its supply chain to ensure more efficient delivery of both internal combustion engine (ICE) and electric models.

As part of its commitment to environmental leadership, Honda is accelerating the electrification of its motorcycle lineup. This includes improving fuel efficiency in ICE models and expanding its range of flex-fuel compatible options.

In early 2025, Honda launched the Active e: and QC1 electric models in India. The CUV e: and ICON e:, designed as global electric commuter models, have already rolled out in Indonesia, Vietnam, Thailand and the Philippines, with plans to expand to Europe and Japan later this year.

In a major strategic move, Honda will begin production of electric motorcycles at a dedicated, high-efficiency plant in India starting in 2028. This facility will focus on modularised models developed exclusively for electric platforms, aiming to boost affordability and scalability in electric two-wheelers.

Through these initiatives, Honda aims to broaden access to electric motorcycles, ultimately targeting the top position in the global electric motorcycle market.

By continuing to launch competitive products and strengthening its supply chain for both ICE and electric vehicles, Honda is positioning itself for long-term profitability. The company aims to achieve a 50 percent global market share and a return on sales (ROS) exceeding 15 percent by fiscal year 2031.

LTTS Secures Multi-Year Deal From Automotive OEM For Engineering And R&D

- By MT Bureau

- January 28, 2026

Bengaluru-headquartered ER&D company L&T Technology Services (LTTS) has announced a multi-year engagement within its mobility segment from an automotive manufacturer. The agreement involves software, connectivity and digital engineering services across vehicle technology domains. This win follows the company’s investments in R&D labs and mobility infrastructure designed for programs with global manufacturers.

The engagement covers mobility engineering capabilities, including embedded systems, digital platforms, verification and validation, cloud integration and cybersecurity. LTTS intends to use its engineering expertise and delivery frameworks to support the customer's technology roadmap.

At present, LTTS operates 22 design centres and 100 innovation labs globally.

The agreement strengthens the partnership between LTTS and the automotive manufacturer in the area of mobility engineering. The company provides design, development, and testing services across the mobility, sustainability, and tech segments.

Alind Saxena, Executive Director and President, Mobility and Tech at L&T Technology Services, said, “We are proud to deepen our partnership with the valued customer through this strategic engagement. LTTS brings together domain-led engineering, secure development practices and excellence in global delivery to accelerate the future of premium mobility. The win reflects the trust placed in our teams and our commitment to delivering world-class engineering at scale”.

Valeo And NATIX Network Partner To Develop Open-Source World Foundation Model

- By MT Bureau

- January 25, 2026

French technology company Valeo and NATIX Network have announced a partnership to develop a multi-camera World Foundation Model (WFM). The project combines Valeo’s research in artificial intelligence and generative modelling with NATIX’s decentralised physical infrastructure network (DePIN) to create an open-source platform for autonomous driving and robotics.

The initiative aims to move beyond perception-based models by creating a system capable of predicting future states and reasoning about physical interactions in a four-dimensional environment. The model will be trained using NATIX’s data network, which has collected 600,000 hours of video data across the US, Europe and Asia over seven months. This data provides the multi-camera inputs necessary for the spatial perception required by autonomous vehicles and robots.

The partnership builds upon Valeo’s existing open-source frameworks, VaViM (Video Autoregressive Model) and VaVAM (Video-Action Model). While these frameworks were previously trained primarily on front-camera datasets, the integration of NATIX’s multi-camera network expands the AI’s field of vision to 360 degrees.

Under the open-source framework, the partners will release models, datasets and training tools. This approach is intended to allow the research community to fine-tune models and benchmark physical AI across various driving conditions and geographic regions. The collaboration seeks to accelerate the deployment of end-to-end AI models by learning from real-world edge cases captured by vehicles in operation.

Marc Vrecko, Chief Executive Officer, Valeo’s Brain Division, said, “Since our creation in 2018, Valeo’s AI research center has been at the forefront of AI research in the automotive industry, especially in the fields of assisted and autonomous driving. Our goal has always been to advance mobility intelligence safely and responsibly. By combining Valeo’s generative world modeling research expertise with NATIX’s global multi-camera data, we are accelerating both the quality and the accessibility of next-generation end-to-end AI models, enabling the research community to build upon strong open models.”

Alireza Ghods, CEO and Co-Founder, NATIX, added, “WFMs are a once-in-a-generation opportunity — similar to the rise of LLMs in 2017–2020. The teams that build the first scalable world models will define the foundation of the next AI wave: Physical AIs. With our distributed multi-camera network, NATIX has a clear advantage of being able to move faster than large OEMs.”

- Tata Technologies

- Amazon Web Services

- InnoVent 2026

- Jaguar Land Rover

- Air India

- ES-Tec Group

- Warren Harris

Tata Technologies Concludes InnoVent 2026 Engineering Hackathon

- By MT Bureau

- January 23, 2026

Tata Technologies has announced the completion of the 3rd edition of its innovation hackathon, InnoVent 2026, supported by Amazon Web Services (AWS). The initiative invited engineering students to develop solutions for mobility challenges in the automotive and manufacturing sectors. The programme received participation from 10,247 students across 404 colleges in India, resulting in 2,822 projects.

The competition focused on the theme of intelligence-driven mobility for the year 2030. Participants received over 650 hours of mentoring and training from subject matter experts to convert their concepts into prototypes. The top 10 teams presented their work at the company's Hinjewadi campus in Pune before a jury of industry leaders from Jaguar Land Rover, Air India and ES-Tec Group.

Team Drushti from CMR College of Engineering & Technology, Hyderabad, secured the first prize of INR 300,000 for a system that customises vehicle infotainment for visually impaired drivers. Second place went to Team The T-Factor from Vellore Institute of Technology, Chennai, for an AI-based breakdown prevention system. Team SwarmSync from the International Institute of Information Technology (I²IT), Pune, took third place for an intelligent fleet management solution using V2X communication.

Tata Technologies offered career opportunities to all 42 finalists involved in the top projects. Furthermore, all participants were granted one-year access to the iGETIT learning platform to study emerging technologies. The finalist projects covered areas such as blockchain for vehicle security, wireless charging for electric vehicles, and AI-led battery monitoring.

The event featured a humanoid robot that performed roles such as coordinating panel discussions and interacting with attendees. A panel of industry experts discussed the global demand for engineering talent and the impact of technology on future mobility.

Warren Harris, MD & CEO, Tata Technologies, said, "InnoVent at Tata Technologies represents our conviction that the future is shaped by those who combine engineering excellence with human purpose to engineer a better world".

Kia India Reintroduces Driver Behaviour Monitoring Tech

- By MT Bureau

- January 23, 2026

Kia India has announced the re-launch of its Kia Inspiring Drive (K.I.D) Program, debuting alongside the New Kia Seltos. The initiative is a driving score system designed to monitor real-time behaviour and provide insights into habits. Accessed via the Kia Connect app, the programme will be rolled out across the company’s connected vehicle portfolio in phases.

The K.I.D score is calculated using a three-month rolling average based on parameters including rapid acceleration, rapid deceleration and sudden starts. To ensure data accuracy, the system applies a weighted value based on the specific vehicle. This methodology aims to reflect long-term driving patterns rather than isolated incidents.

The programme incorporates community-based leaderboards, allowing owners to compare scores and track their standing within the Kia community. By turning road safety into an interactive experience, the manufacturer intends to encourage responsible driving through recognition and competition.

The behaviour-based scoring system provides data to help users understand the impact of their habits on road safety. Kia is supporting the re-launch with a digital and press campaign to increase awareness among its customer base.

Atul Sood, Senior Vice-President – Marketing & Sales, Kia India, said, “Safety remains at the core of Kia’s philosophy, and with the re-launch of the Kia Inspiring Drive program alongside the New Seltos, we are taking another meaningful step towards encouraging responsible driving behaviour. By offering customers clear, data-driven insights into their driving patterns, the KID program empowers them to make safer choices on the road, while also enhancing their overall ownership experience.”

Comments (0)

ADD COMMENT